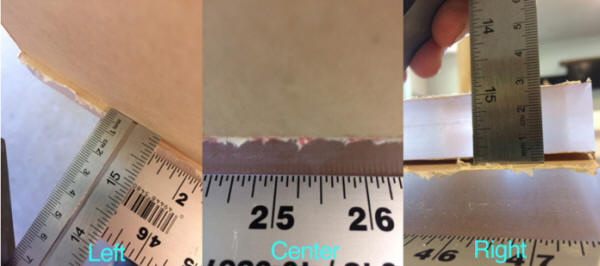

Tenecor tank bow concern 9/18/19

Good morning ,I have a question about my fish tank . It has a 1/2 inch bow

across the front top to bottom that has been present for a number if years .

I.e. 1/2 at top and 1/2” at bottom and looks like a parenthesis ) .

<Like this description>

I have an acrylic 180g 72x24x24 tank that was purchased new from Tenecor and in

service since 2001. It has “ rolled” front corners ( i.e. no seam ) . Front and

sides and bottom are 3/8” acrylic as is the top brace ( with cutout openings for

access ) .

<Mmm; well, I'd have made all of 1/2" at least>

The back is 1/2” . It sits on an acrylic stand .

I am concerned about the bowing and safety of the tank . The bow had been

present for years . All the seams look good and there is very little crazing I

note that just about all tanks this size now are made of 1/2 “ or thicker

acrylic .

<Ah yes>

Tenecor has gone out of business long ago .

<Correct>

This tank is in our living room . Your thoughts would be appreciated

Thx Jimmy

<Well, all tanks "bow" to extents, and given your note of little crazing and

good seals, I would not be concerned here. Put another way, I myself would

(continue to) use this tank as is. Bob Fenner>

Re: Crazing... Bowing

3/19/18

Thank you for the quick response. I just put a level to the front panel,

definitely at least a half inch bow in the middle.

<Typical for a commercially made acrylic tank of this size/dimensions>

Bottom of the front panel is level. I also put the level across the top of

the tank lengthwise and the middle wasn’t touching the level at all, maybe

1/2 inch gap. Is this a big concern?

<Not a big concern. BobF>

Bowing... Earl's input

3/19/18

Hi one more question for you. My acrylic tank is 72 inches long. If I run a

48” level across the middle of the viewing panel, there’s a gap of at least

1/4” on each side of the level. Is that cause for concern? If I run the

level vertically across the center there’s like and inch gap on each side of

the level. How concerned do I need to be? Thanks again.

<Hi Randy. The first question you should really consider is a simple

risk/reward factor. Is it really a risk you're willing to take? Can you

level it out? I sure wouldn't leave it an inch off-kilter if I could correct

it, if only for peace of mind. -Earl>

Re: Crazing.... bowing 3/19/18

If I hold the level on the front panel, starting from the right end half way

up, the end of the level on the left side close to the center of the tank

there’s like an 1.5 inch gap or bow.

How big of a concern is this? Am I measuring it correctly?

<Not too surprising... and yes for the measure you're doing>

Re: Bowing

3/19/18

Thanks. I will be replacing my tank in a month or so. I want to know how

urgent a situation I’m currently in. The tank is level when I place a level

across the top but the viewing panel is bulging. I just don’t know if the

amount of bulge is acceptable or an emergency situation?

<Not an emergency. B>

Re: Bowing 3/20/18

Thank you, much appreciated

<Glad to set your mind at ease. Bob Fenner>

|

1" thick acrylic is warped over a 5 ft Span

10/20/17

Hi

I'm building my own tank and have a slight issue with a warped piece of acrylic.

The piece is 12" wide by 60" long and 1" thick. I picked up the 1" stuff for the

tank. I looked at the coast to coast external overflow box pieces. 12"x60". In

the picture you can see that across the length I have a warp of about 3mm. The

"right" end of the picture is with both pieces laying flat and you can see the

warp. The edge is straight on the piece it will attach to. Checked with a

straight edge. Thinner stuff no prob to straighten it out. 1" not so easy. Is it

do able with clamps, shims and heat?

<Mmm; is the warp just in the "run", not the "rise" of this 1" material? IF so,

then I'd leave as is. IF the rise is off this much, you'll need to do

something.... re-cut it to flush before solventing>

I don't really want to router off 3mm extra in the middle after glue up (wood

term :)))). Right now I have placed a small 3mm spacer under the middle of the

warped piece and weighted the ends. If it gets warm enough outside today do you

think the warp will fix itself or is it something that requires more than 90

degree heat? Heat gun or hair dryer? Any ideas?

<Heat and time will help the material to relax. Heating with a hair dryer I

don't recommend. Do you have a plastics fabricator/shop nearby? They may have an

oven to do this job for you>

Cheers

Dana

<And you, Bob Fenner>

|

|

Acrylic tank repairs

11/15/16

Hi guys, I have a question or two for you all. I bought a old 8x2x2 tank off

Craigslist for cheap.

<Ahh; an olde stock 240>

The tank was pretty rough when I got it. The top brace was cracked all around

one of the opening on top which I patched with Weldon 16 and another piece of

acrylic/Plexi.

<Good>

I'm not sure if the tank was made of acrylic or Plexi or??

<Both common names for the same compound... though "qualities" vary>

Anyhow, the top had 4 access holes in it. The people before me had cut the top

brace within a 1/8" to the back panel and did a terrible job. They did this on

both sides of the tanks and said it was because they used to have a hob filter

on it.

<Still; not a good idea>

Because of this the tank had some bowing in these spots while dry.

Before I read this site I went ahead and used large clamps to pull it back to

normal and used Weldon and patch to secure it, is this going to be OK?

<Likely so>

Also there was some crazing along the back pain Seams so I used Weldon 16 to add

on a 3/8 square dowel in the seams with crazing will this help?

<Not likely; no. The crazing is permanent>

If needed I can send pictures. The guy I bought it from said it never leaked but

I wasn't convinced even though he seemed pretty honest. Any suggestions would be

great thanks.

<Enjoy your new tank. It appears you're aware of the most important/dire issues

and have addressed them. Bob Fenner>

|

Acrylic tank reinforcements

2/8/16

Hey there,

<Michael>

Thank you for all the info you've put out there- very helpful.

<Welcome>

I acquired a 350 gal tank in the shape of an irregular pentagon (photo

below)

<Wow! Very nice. Let me make an important statement here (particularly for the

many browsers that will read this: BE VERY CAREFUL re the stand, support here.

IT MUST be PLANAR and LEVEL... check it as the tank is filling, with a long

level and possibly a true board to support the level... "odd-shaped" tanks,

particularly ding dang "L" shaped ones very often fail due to troubles w/o such

support>

The tank is 36" high and made with 1/2" acrylic.

<Mmm; I wish this was 5/8" or even 3/4"... there are different qualities of

acrylic... Some imports are "soft">

The two largest panels are 48" and 56" long. When filled with water the amount

of bowing on these panels and top frame made me uneasy.

<Yikes>

I drained, placed 2x4s between the panels and the wall and refilled.

Much less bowing! I'll also mention that I installed 1/2" square rod along the

bottom and vertical seams

<Am relieved re this last. I might well do the same with the verticals, indeed

all remaining inside seams.>

So the questions:

Is it safe to frame around the tank to minimize the bowing or will that simply

place stress in another area?

<Am dubious as to the long-term structural value here>

Assuming the first scenario won't work, I will lower the water level. What would

be a maximum recommend height for the water?

<Can't tell from here... again; I'd be using doweling in all corners>

Thank you!

<Welcome. Bob Fenner>

|

.JPG)

.JPG) |

|

Re: Acrylic tank reinforcements

2/8/16

Bob, the quick response and advise is much appreciated!

<Glad to proffer it Miguel>

Even if the framing may not be necessary, it would make me sleep better at

night��. What is a "normal" amount of deflection on a 36x56 panel?

<And acceptable... No more than a half an inch IMHO. BobF>

|