|

FAQs about Stands, Supports for

Aquariums: Leveling

4 Related Articles: Aquarium Stands, Marine

Tanks, Canopies, Covers &

Lighting Fixtures,

Related FAQs:

Leveling 1, Leveling 2,

Leveling 3,

Aquarium Stands 1, Aquarium Stands 2, What to Use, About

Floors Underneath, DIY, Finishing/Coating, Commercial, Modification, Repair, & Tanks, Tanks 2,

Tanks 3, Tanks 4, Aquarium

Repair 1, Acrylic Aquarium

Repair, Used Aquarium

Gear, |

|

|

Metal Stand Leveling and Stand Top

1/30/20

Hi,

<Howdy Bob>

I have a metal stand that is 50" long and 18" wide. It has 6 feet, 4 at each

corner and two mid way in the front and back.

<See this in your pix>

The feet are vertically oriented angle iron (1"). It is going on a tile

floor. Currently it is unfilled and I am putting my system together. I

currently have round slider/floor protectors on each foot with 2 pieces of

indoor carpet in the protector. Display tank is standard 90. Sump is 40

breeder. Pictures attached. I believe the stand is square and true. (Floor

level and top of tank levels are the same)

A few questions:

1. I don't think I need a piece of wood to top the stand for display tank.

Agreed; IF this stand is level, planar... should be fine>

2. Is my "foot" setup ok? Do I need anything? If so, is there something

better than my slider/carpet concoctions?

<I think you're fine here. I do want to ask re the floor... this is on a

concrete slab, like the ground floor? The who shebang will weigh about 1,300

lb.s... >

3. The floor slopes 9/16" down to the right and 3/16 down towards the front.

What is the best way to level this?

<Oh! To put a treated, sealed piece of substantial plywood (1" or more)

under ALL feet and shim this (twixt the ply and tile) in a few places

(plastic shims). CHECK for level a few times as you're (test) filling... as

the floor may move. AGAIN, tell me what is under the tile>

4. For my sump, I have a thin press board sheet. Is this ok?

<Likely so; as long as this too is water-sealed... I can't make out the

support for the bottom rack of this stand. Was it built to have two

aquariums on it? I don't recognize the design>

My thought is that I will be biasing it to the back, maybe even overhanging

an inch or two to make the plumbing more vertical (vs. having to curve under

the DT more. If not biased, the tank sits directly on the left to right

rails, but the front to back braces gap the thickness of the angle iron

since they are welded under the left to right rails.

<DO put material under the entire bottom tank/sump edges>

I looked for answers to these questions extensively in your site but didn't

find the same questions. I appreciate your help!

--

Bob McCurrach

<Glad to help. Bob Fenner>

|

|

|

Re: Metal Stand Leveling and Stand Top

1/31/20

Hi,

<Hello>

Thanks for your advice. A few questions below to make sure I understand

and answers to your questions. Adding new pics.

<Ok>

Thanks!

> Subject: Metal Stand Leveling and Stand Top

> Hi,

> <Howdy Bob>

> I have a metal stand that is 50" long and 18" wide. It has 6 feet, 4

at

> each corner and two mid way in the front and back.

> <See this in your pix>

> The feet are vertically

> oriented angle iron (1"). It is going on a tile floor. Currently it is

> unfilled and I am putting my system together. I currently have round

> slider/floor protectors on each foot with 2 pieces of indoor carpet in

the

> protector. Display tank is standard 90. Sump is 40 breeder. Pictures

> attached. I believe the stand is square and true. (Floor level and top

of

> tank levels are the same)

> A few questions:

> 1. I don't think I need a piece of wood to top the stand for display

tank.

> Agreed; IF this stand is level, planar... should be fine>

> 2. Is my "foot" setup ok? Do I need anything? If so, is there

something

> better than my slider/carpet concoctions?

> <I think you're fine here. I do want to ask re the floor... this is on

a

> concrete slab, like the ground floor? The who shebang will weigh about

> 1,300 lb.s... >

>>It is a cement slab, ground floor. Very solid.

<Good>

> 3. The floor slopes 9/16" down to the right and 3/16 down towards the

> front. What is the best way to level this?

> <Oh! To put a treated, sealed piece of substantial plywood (1" or

more)

> under ALL feet and shim this (twixt the ply and tile) in a few places

> (plastic shims). CHECK for level a few times as you're (test)

filling...

> as

> the floor may move. AGAIN, tell me what is under the tile>

>> Is 9/16" side to side a big number here for out of level? Meaning way

out needing very special consideration?

>> Is 3/16" back to front a big number here for out of level?

>> Do you mean a plywood sheet slightly larger than the footprint of the

tank? That is a significant piece of wood. Wouldn't this flex if I shim

at

3-6 places? Or do shims need to be around the whole perimeter? This

seems

difficult.

>> Seems that metal stands are a pain with their own issues.

>> Or are you saying, 6 individual pieces, one for each foot?

<I'd put/use one piece, under all six feet; one inch (marine if you can

find, afford it) ply. Hard, plastic shims under the plywood.>

> 4. For my sump, I have a thin press board sheet. Is this ok?

> <Likely so; as long as this too is water-sealed... I can't make out

the

> support for the bottom rack of this stand. Was it built to have two

> aquariums on it? I don't recognize the design>

>> I bought this off of craigslist. He is a welder and custom built.

Pics

attached.He sent me many pictures about the build process. The design

does

look similar to metal stand pictures I have seen on the web. The bottom

rack has a mitered corner rectangular frame made of 1 1/4 angle iron, 48

1/2" x 18 1/2". The cross supports are 1 1/2" x 1/4" bars welded under

the

angle iron, There are 4 of them. The outer 2 line up with sump tank

ends,

but they gap to tank by the thickness of the angle iron (1/8" thick). I

have filled the tank and sump for a few weeks to test out his overflow

and

return (which I am re-designing). Everything seemed very solid.

<And this person/welder warrants that a full system's weight can be

supported above w/ these bent legs? I'd get that in writing just in

case>

> My thought is

> that I will be biasing it to the back, maybe even overhanging an inch

or

> two to make the plumbing more vertical (vs. having to curve under the

DT

> more. If not biased, the tank sits directly on the left to right

rails,

> but

> the front to back braces gap the thickness of the angle iron since

they

> are

> welded under the left to right rails.

> <DO put material under the entire bottom tank/sump edges>

>> Makes good sense since if I want to bias back. Will replace my press

board with more substantial plywood. How thick do you think is needed

here?

<Same as above, 1" or more>

How much do you think I could safely overhang? 1"? 2"?

<The (not pressed) plywood likely fine with 2">

> I looked for answers to these questions extensively in your site but

> didn't

> find the same questions. I appreciate your help!

> --

> Bob McCurrach

> <Glad to help. Bob Fenner>

<And again, BobF>

|

|

Re: Metal Stand Leveling and Stand Top

2/1/20

Hi,

Sorry to have so many questions.

<No worries; clarity and completeness is my/our aim>

1. For 1" marine grade plywood, seems on 3/4" is most commonly the max.

Can I wood glue, 2, 1/2" thick ply together and get similar rigidity?

<I'd just go w/ the 3/4" (sealed) alone. >

2. Is the idea that 1" is rigid enough to not deform when shimming?

<To extents, yes>

3. Do I need to shim along the whole perimeter or how far apart can the

shims be?

<Mainly under the leg areas (I would use the coasters you have, but also

under the space/span between the feet>

Thanks,

Bob McCurrach

<Welcome. B>

Re: Metal Stand Leveling and Stand Top 2/1/20

Hi,

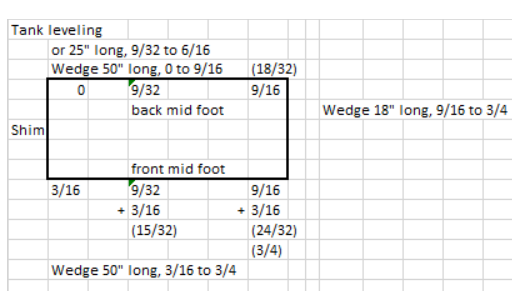

Me again! So when I look at the numbers under each foot, for 9/16 down

right, 3/16 down back to front:

[image: image.png]

<See your figuring>

-Do these numbers look about right?

<Could be... likely the floor more than the stand; but yes>

-You mentioned shimming between plywood and floor. Wouldn't it make more

sense to have the plywood on the floor and 6 appropriate height blocks under

the 6 feet (actually 5 since back left is 0). This way the whole surface of

the ply is on the floor distributing load (vs. with shims under ply, only

having spotty perimeter loading on the floor)

<In actual practice, no... how to put this? Better to have support under ALL

the surface area piRsquared of the coasters, and have this weight

distributed on a number of plastic wedges. IN SOME CASES, folks use a good

two by twixt the wedges and ply... but the amount of mass here, on a

concrete slab. I'd do as I've suggested continuously>

-Of course I may be over thinking this...but would like to look at it from

all angles while it is just design...

<DO take your time; VERY important>

-I think I hate metal stands know, but I really need the room underneath for

my big ole sump.

<Understood. BobF>

Bob M.

|

|

|

|

Acrylic Aquarium build. 1/20/19

Hi guys/Bob,

<Good morn Mike>

I’ve built a custom (cell cast) aquarium 60”X36”x 24.5” high top and are 1/2”

acrylic, side panels are just shy of 3/4” acrylic. Joint gaps before glue are

.02”. Glue used is Scigrip 42.(you can’t beat 4000psi) Some small bubble here

and there and some crazing. Tank holds water fine. Long side panels bow measured

from Center with a two foot level,

<A note here: I'd use a longer level... >

I get a 1/16” gap from left to right at either end of level. From top to bottom

I get 1/8” gap at either end of my 24” level. Is this bowing ok?

<Mmm; likely so; considering the thickness of acrylic used here. Are you sure

the stand itself is level?>

I get very little bow at the short ends of my tank. I drained half the water and

found the bow very similar than when the tank is full.

<Ah, yes; the material is not going to bow itself>

I was planning on running an old Tunze wave box on the tank as part of a stress

test to test the seams. Tank panels were laser cut and all lasered edges were

shaved off till stress bowing of the panels were relieved.

<Oh! Neat! Not a worry then.>

One of the well known tank manufacturer wanted to make this tank out of 100%

1/2” acrylic. I totally didn’t want that!!!

<Agree/d>

Thanks for your help.

Mike

<Thank you for sharing. Bob Fenner>

|

.jpeg) .jpeg) |

|

Problems with 20 gallon aquarium rack

6/18/18

Hello:

<Tim>

I am having some trouble with a 20 gallon aquarium rack that I built and I am

looking for some advice.

I built the rack out of 2x4s following this video here:

https://www.youtube.com/watch?v=3ffely-t4iw .

<Have reviewed>

I used a circular saw for all of the cuts, but a lot of my cuts were not

straight. I am very amateur

when it comes to woodworking and I did not do that great of a job. I tried my

best using a carpenter's square and a miter square to get everything squared up

as I was building it, but I seem to have failed that. The rack came together

fine but when I bought it in the house to test out to see if it was level or

not, it rocked.

<Best to use the level while assembling>

I checked the floor with a level and it was level. The rack is actually going in

the garage so I was planning on putting some leveling feet on it, which I did. I

was able to get it level to the garage floor, which is slightly sloped for

drainage reasons.

Anyways, after I leveled it, I put an empty 20 gallon tank on the top of the

rack and it rocked.

<Not good>

It seems that the back left corner and the front right corner are too high. As

you can see from the attached picture, the gap created is quite large! I checked

the middle and bottom and both of these have the same problem as the top. I was

scratching my head trying to figure out what I could do to fix this, so I went

and got some plywood cut to fit the rack to turn it into a shelf. After adding

the plywood, the tank still rocks! Why is this?

<The laterals are still not level...>

I am unsure what to do at this point. I see a lot of people using some type of

foam under the tank to help with minor issues, but I feel like the gap is too

big for this.

<I agree>

Is my best bet going to be to take down the corners with either sandpaper, a

wood chisel, or a plane?

<Mmm; no... wedges under the ply that make the plywood itself level is best. If

necessary for smaller gaps, you can put foam between the ply and tank>

I am worried that if I attempt this, I am going to end up taking too much wood

off and end up needing to rebuild the whole rack, which I really don't want to

do. I think I did a decent job for my first attempt at building such a rack, but

obviously not good enough!

What do you recommend in this situation?

<Plastic wedging (you can buy in various sizes at Home Depot, Lowe's....)

as stated>

Thank you for your time,

Timothy Marinello

<Please write back if this is not clear, complete. Bob Fenner>

|

|

tank support... reading

5/2/18

just built a custom built in stand for 120 gallon tank.. its a tight fit

. had tank in empty and there has been some settling. anyway to

shim the tank itself

<... not the tank>

and how much unevenness will 1/4 Styrofoam compensate for.

<... about a sixteenth>

don't know if I have asked the right or enough questions but thanks for

any input. cheers Morgan

<Read here:

http://www.wetwebmedia.com/aqstands.htm

and the linked files at top. Bob Fenner>

|

The best of times the worst of times. Little glass chip and stand

leveling input to share 2/28/17

Hi WWM Crew,

<Eddie>

"It was the best of times, it was the worst of times." Sorry to get all

"literary" with you, but it seemed to describe accurately my dilemma. It was the

best of times in that, finally, after four and a half years without a fish tank,

I am ready to get wet again.

<Yay!>

The stand was built, the plumbing and sump were worked out in the basement, and

this past Saturday a friend and I moved the stand and tank into the den. I

worked for a couple of evenings on and off getting it perfectly level. I even

learned a couple of neat tricks that I will share below.

The tank is now level and ready to be filled beyond the 2 3/4" that I have

already put in it to level it.

It was the worst of times in that last evening, while I was finishing up the

leveling, I noticed a chip in the front left corner of the tank (see picture).

<I see this>

This tank is a 75 gallon with the overflow offset in the middle of the left half

of the rear of the tank (I think it's an AGA). I got it slightly used four years

ago, and it has been sitting in my basement since then.

When I first got it in the basement, I went over it with a fine tooth comb and

did not see this chip. I'm sure I would have if it had had it then. It must have

happened some time since then. I have also looked over it several more times

since then, but not as carefully. We have been very careful moving it around,

and we didn't bump it into anything any time we

moved it.

<This is a small "impact" chip, scalloped... IF one had to have one, the better

kind>

I've had it filled several times--right after I bought it, to check the stand,

and to check the plumbing/sump. Each time it was filled for several days (once

for a week). The last two fillings were recent (the plumbing check was last

month). I'm virtually certain the chip was there then. I know we didn't bump it

into anything carrying it into the house, and nothing has been bumped into it

since then either. In fact, nothing has been bumped into it at any time (that I

know of). The source of the chip is a mystery.

I have looked over the chip FAQs several times over the years (out of concern

for other tanks for potential sumps/QT's), and looking at the information there,

it is not the nature of the chip that concerns me. It is a "sea shell"

chip with no cracks that is about 1/8" in diameter. It is too shallow

to measure the depth effectively. I tried to take a side-view

picture and you couldn't even see it. What concerns me is where it is.

It is about 2 1/2" to 2 3/4" from the bottom of the tank (measured from

the inside by the depth of the water). It is toward the outside of the glass

panel though (not on the side with the silicon). For this reason, I decided to

seek "professional help" in assessing it.

<I'm not overly concerned re the size, placement>

I don't mind admitting that it makes me nervous. My last marine aquarium was a

55 gallon that the bottom panel burst mysteriously in the night.

Actually it wasn't so mysterious because the stand top was not planar and I

don't think the tank was completely level either (though it was hard to tell

after the fact).

<Yikes>

THIS stand is planar with one tiny gap (less than 1/32") on one corner. I have

used 3/4" Styrofoam underneath the tank to solve that problem. The tank is

perfectly level now (with less than three inches of water) and I intend to keep

checking it as I fill it--if I get to fill it, which is what I'm hoping that

your professional eyes can tell me. I think I know the answer, but is this tank

safe to use? Or do I need to save my pennies for another one?

<I would use it>

I also wanted to share a couple of tips that I learned while leveling the tank.

It may be old information to many, but I don't recall reading them anywhere on

WWM. I have read about putting a couple of inches of water in the tank and

measuring the depth to determine whether it is level. What I discovered is that

it is easier to use a yard stick than a tape measure.

Also, I discovered if I put a small piece of painter's tape on the yard stick to

mark where the water depth was when I measured the first corner that it made it

a lot easier to determine whether the other measurements were the same or not.

It was either right at the tape mark or above or below it. I only taped one side

of the markings so I could tell how much

from the other side. Also I discovered that it helped to draw a rectangle

representing the tank from above and write at each corner and in the front and

back middle the depth so I could look at all the measurements at the same time

and decide where the shims needed to go. Hope someone finds this helpful.

<Thank you for sharing>

As always I thank you SO MUCH for making this service available. I have learned

so much over the years from the site and the few email inquiries I have made.

Thank you,

Eddie

<Welcome. Bob Fenner>

|

|

|

|