|

FAQs about

Overflows, Bulkheads/Through-puts,

Stand-Pipes, Holes vs. Boxes... Sizing, Number,

Placement 3

Related Articles: Overflow Box Arrangements,

Plumbing

Marine Systems by Bob Fenner, Myth of the One Inch

Beast (Why Relying on One Inch

Overflows... or Overflow! Is foolhardy) by

Scott Vallembois, The

Flowrates through various Bulkheads (In relation

to overflow drains) by Scott

Vallembois, Plumbing Return

Manifolds, Refugiums,

Related FAQs: Through Puts Placement/Number/Size

1, Through-Puts

2, Through-Put Sizing/Number/Placement

4, Through-Put

Sizing/Number/Placement 5, Through-Put Sizing/Number/Placement

6, & Overflows 1, Overflows 2, Overflows 3, Overflows 4, & FAQs on: Rationale/Use, Through-Hull Fittings, Hang-On Selection, Plumbing, Troubleshooting/Repair...

Marine Plumbing

1, Marine Plumbing 2,

Marine Plumbing 3,

Marine Plumbing 4, Marine Plumbing 5, Marine Plumbing 6, Plumbing 7, Plumbing 8, Plumbing 9, Plumbing 10, Plumbing 11, Plumbing 12, Plumbing 13, Plumbing 14, Plumbing 15, Plumbing 16, Plumbing 17, Plumbing 18, Holes & Drilling, Durso Standpipes,

Make Up Water Systems, Pumps, Plumbing, Circulation, Sumps,

Refugiums, Marine Circulation 2, Gear Selection for

Circulation, Pump

Problems, Fish-Only Marine Set-ups,

Fish-Only Marine

Systems 2, FOWLR/Fish and

Invertebrate Systems, Reef

Systems, Coldwater Systems,

Small Systems, Large Systems, Water Changes, Surge

Devices,

|

Calculator, plumbing,

flow-rate 12/16/07

Bob, This calculator seems like it would

be useful, what do you think? http://www.aquaticeco.com/index.cfm/

fuseaction/popup.calc_pumphead James <Best one I've

ever come across. Will post/share.

BobF>

|

|

Possible Megaflow solution??

Plumbing questions?? 12/22/08 Hey guys, Thanks for

the great site! <Thanks for visiting, hello!>

Here's my current dilemma. I just attempted to install

a "Glass-Holes overflow kit" on my 72 bow. They

offer a 2x1.5" overflow box that runs 1500gph. The

issue here, is that the overflows are predrilled in the

rear of the box at aprox 3" apart. I bet you can guess

the next part.?? <Hmmm, no.> Well, I assumed that

this sounds logical and worked well in the video on their

site. <And for 1000's of installs around the

world.> So I started drilling as per the attached

template and instruction, hole one-ok,...hole two-looked

ok. After I wiped away the milky film, I saw a nice thick

hair line crack between the 2 holes. After discussing this

with a glass company, they said to stay 8" apart min.

on holes. <Based on what? This is quite an arbitrary,

ridiculous number. Many factors are involved: glass

thickness, hole size, height of the tank, and placement

within. The tried and true industry standard is one hole

width apart. Take a look at the Oceanic Tech series, many

holes drilled mere inches apart.> Ahh... Hindsight!!

<Really just the risk one takes anytime drilling glass.

I do own a stake in the Glass-Holes.com company, do contact

us re a refund of your purchase if you wish, we do stand

behind what we do!> So I now have a 72 bow

turtle/reptile tank. OK, now that, that's done, the

reason I am writing is I am now looking at a new 90 gallon

reef ready tank setup. This new 90 gal RR tank will feed a

30 gallon sump with a 300micron sock, a ASM G2, 2 sets of

baffles and a return compartment for internal pump and

heater. I may also hang a HOB CPR 19"x4"x12"

fuge on the sump as well. I will be keeping softies, LPS,

and possibly SPS once I get MH lighting. I can't afford

big $$ on a custom tank, and it seems the only option that

I have found in the Chicagoland area is the terrific

"Megaflow"...... <As you imply, not so

"Mega".> So, I started thinking on how to make

the Megaflow, flow better. What is your thought's on

this. Using both the 1" drain and the 3/4" return

for drains to the sump. <Honestly common practice with

these. Do note that these holes here too are drilled within

8" of each other.> Then as a return line, I want to

use a 3/4" SCWD, and just feed back into the tank with

2- over the rim returns/modular fittings--one on each

corner. <A fine way to route returns.> So could I

assume that total drain to the 30 gal sump is 1-

3/4"(aprox. 300gph) and 1- 1" drain(aprox.

600gph)=total drain to sump approx 900 gallons(this of

course does not include any 90's or restrictions)? Is

this at all close? If it is not correct, what would you say

the flow would be? <Not really. A 1" will only flow

300 gph safely, with a ¾" about 160

gph.> What mag pump would you recommend to return via a

1" flex into a 3/4" SCWD, then out to the corners

and over into the tank? <A Mag 5, maybe 7 with a ball

valve to control the amount of flow. Neither leaves you

with any overflow redundancy.> Does this idea of using

the additional 3/4" drain sound like it's worth

the time and effort? <It is worth it with these

things.> Is there a better way? <Drill it, even if

just one 1.5" drain through the back, within the

Megaflow box.> What is the best way to plumb the 2

feeds? 2 Dursos? <In this scenario yes.> Is there any

way to get better flow from the "MegaFlows"?

<A new product we/GH are currently working on, not quite

there yet.> Should I stay away from the MegaFlows? <I

in all honestly would.> Any better, economical options?

<The one you bought IMO, just a bad turn here. Like I

say, it can and does happen sometimes whilst drilling

glass, or drilling wood/anything for that matter.> So my

other thought to gain some flow in the new 90 gallon

megareef tank, besides a single Koralia 3, is to drop a

pump into the rather large Megaflow overflow chamber and

use the factory Megaflow modular return as an internal

closed loop(since I am using the 3/4" return as a

drain) . Any thought on this? <This can work so long as

the intake and output of this pump are drilled through the

overflow box. Otherwise it will affect the amount of water

in the box, creating many other issues.> What MAG pump

would you recommend to use in this Megaflow cavity for

return? <Would not, a traditional closed loop or

powerheads are a far better way to go.> Is there a

better pump for less heat then the MAG? <Eheims,

Oceanrunners, among many others.> Also, what do you

think of this setup as a whole(drains--1-3/4",

1-1"------return possible mag 7.5 or 9.5 thru SQWD

into 2 returns-----small pump in the Megaflow cavity thru

factory return-----Koralia 3 across top of rocks? <See

above.> Does this sound like enough flow for SPS's?

Should I use another Koralia 3, one on each end? <I

would for SPS here.> What is ideal flow, although-not

direct flow, 15x-ph, 20x-ph? <On the higher end

here.> Why can't AGA see the need for bigger drain?

<A question I have asked for years.> Thanks for all

your time and thoughts on this. Randy-Chicagoland

<Welcome, best of luck, Scott V.>

Re: Possible Megaflow solution?? Plumbing

questions?? B-feel free to post PDF 12/24/08

Hey Scott, Thanks for the info and the timely response.

<Hello again Randy, happy to assist.> I have been in

the fish hobby for 18 years(13 fresh, 5 salt), and I find

the info from this site is 2nd to none. <Thank you!>

It has been a constant, reliable resource for anything fish

related. I send thanks to you and all of your partners for

this! <Will be seen/passed along!> I do have a few

other questions if you don't mind. Also, by no means

was I bashing GlassHoles.com, I found their

product/overflow box to be of excellent craftsmanship.

It's a cool setup and a way to get the surface skimming

without losing lots of space. <Ah, no worries. Not

perceived as a bash, just want to help you and others out

where I, we can. I do apologize if my response seemed

defensive.> It's just a bummer that I drew the short

straw this time when drilling! <Tis the case, it does

happen, but stinks.> I have thought about trying another

tank and putting the overflows on each corner but knowing

my luck I may have the same results.?? <Consider

visiting a glass co and acquiring some scrap to practice

on, you can easily get 20 holes or so out of the bits.>

So, as my plans are still pretty liquid in structure

regarding the new tank setup, I am now narrowing my choices

down based on drain size and flow. With this said and after

reading both good and bad reviews about Glasscages.com, I

am looking either their 90gal(48x18x25) or a

oddball-125Tall(60x18x25). <I have dealt with many

customers using their tanks. The general consensus I have

heard from them is good for the money; perfectly

functional.> Most likely it will be the 90(based on wall

location and size). Glass cages will drill what ever I

want, wherever I want(I know this is a little possible with

AGA and Oceanic, but seams to be more difficult based on,

LFS, dist, Aqueon's involvement). <They will, but

dealing directly with the builder does have advantages.>

BTW, to refresh, My setup-- 90gal will have 1 overflow in

the rear center(overflow and drain size/qty to be

determined), it will feed a 30 gal sump(currently setup for

2-1.5" intakes) into a 300mic sock, ASM G2, 2 sets of

baffles, then return pump in final compartment. I may add a

18x4x12 CPR HOB fuge onto the sump. Return will have a 3/4

or 1" SCWD and either thru tank(high) or over the top

modular returns. Tank will have 1 or possibly 2- Koralia

3's. So here are my questions: -My overflow box will be

drains only and will not be used for any returns. If you

had a perfect world to live in, and were asking for the

ideal flow for the 90 w/center rear overflow, what would

you want with my 30gal sump? 2-1.5"?, 3-1.5"?,

2-2"? 3-2"?? <Dual 1.5� or

2� will do the trick. You do want to have

a 100% redundancy in case of a drain plugging/failure.

Taking this into consideration the dual

1.5� will allow you 750 gph, while the

dual 2� will give you 1300 gph, both of

these scenarios offer 100% redundancy.> I am going to

try and design this as best as possible for SPS's, but

it will be in the family room and noise needs to be as low

as possible. -How far apart do the drains need to be for

Durso clearance? <Not too far, the width of a PVC

elbow.> Do you know how wide the top of a 1.5"

Durso is? <Whatever the width of the elbow/fitting is,

2� or so.> -I think Glass cages std.

overflow is a 6"x10". <Plenty of room.> For

the above "ideal" drain info , ideal drain number

and sizes, what is the perfect overflow box size? <A

loaded question for me! The 6X10 is fine.> I know

it's based on linear flow? <Not really, more a

matter of bulkhead size. Linear overflow length is highly

overrated in the forums nowadays.> Not sure how noise

and suction plays into it? <Suction should not play into

it at all with these appropriately sized drains. Noise is a

function of the amount of water flowing and the Durso you

will use.> -What do you think this will put my GPH thru

the sump at? What's ideal sump GPH? <Flow does

depend on the pump ultimately. Ideal IMO is 600-900 for

manageability here.> -Should I run a Y and 2 sea swirls

instead of the SCWD? <You could, this is all about

implementing the flow you have, see here:

http://www.wetwebmedia.com/circmarart.htm > -On my

return, based on the above drain number and size, which MAG

pump do you recommend for the SCWD? <A Mag 9.5>

-Which SCWD(3/4" or 1") do you recommend based on

above drain number, size and return pump? <A

¾" for one return, dual ½"

for two.> -My returns, is there any

advantage/disadvantage to going thru the tank or going over

the rim? <The big disadvantage with drilling these is

siphoning into your sump when the return pump is off; this

will happen with over the top returns also, just usually to

a lesser degree. The advantage is merely aesthetic to

some.> Where is ideal placement if I go thru the glass?

< If you do drill you will want to do so as high as

possible, making sure your sump will have the capacity to

handle all the water that will end up there in a power

outage.> -With the sump return and the 2 Koralia

3's, is there any need for a closed loop? Location??

<Hmmm, no need with the 3�s. Powerheads

are the way to go IMO. Just so much benefit re

adjustability and power consumption.> -Will the 18x4x12

CPR HOB fuge(on sump) do me any noticeable good or is it to

small to do any good for the 90gal? <Bigger is better,

but something is better than nothing. You do not have room

to divide off a section in the sump?> -Any thoughts on

Glasscages.com? <Stated above.> -And last, I have

always used MAG pumps, what do you recommend in it's

place that is more efficient and less heat without breaking

the bank? <First choice is Eheim, cheaper second is the

Oceanrunner series.> Thanks again for all the time

dedication to this awesome site. Randy <Thank you. I do

urge you to either contact us at Glass-Holes.com re a

refund if you do not intend to use the box or have the tank

drilled by Glasscages for the G-H box (I have attached a

PDF for hole location you can send them if you do go this

route). This is too much to spend and not use or get

reimbursement! Best, Scott V.>

|

|

Improved filtration/Overflow, sump setup

11/24/08 I recently set up a new 135 gal Oceanic reef

tank. I converted my old 55ga tank into a refugium underneath.

The refugium is a simple design. It consists of three

compartments, divided by two acrylic sheets. The first

compartment is where I keep my skimmer and heaters, this spills

into my second compartment, which contains some live rock rubble

and Chaeto algae, and then the final compartment simply contains

my two return pumps. The volume of the system is approximately 40

gallons. My question is do you think this simple design will be

very effective? <Yes, tis the setup nowadays.> Could I

improve on it by putting a small pump (200 gph or so) in the

final compartment and pump the water that was going to go to the

display back to the first compartment to run through the process

again so to speak? <No, you want the raw water from the tank

running to the skimmer.> Also, I'm not sure what my two

overflows are rated at (if that means anything). <Typically

1� bulkheads, good for a bit more than 300 gph

per, though �rated� much

higher.> My return pumps are rated at 740 gph ea (again

ratings don't seem to mean much). <Nope.> The water

level draining at the teeth on the overflows is not even half way

up the teeth. <Not a factor, the bulkhead is the limiting

factor here.> Last question, can it handle more return?

<Likely not.> Is looking at the water level on the teeth a

half-way accurate way to judge this? <No, see above.> Thank

you Corey <Welcome, Scott V.>

Re: Revised Tank Plan (Last one) Revised Tank Plan

9/1/08 Crew, <Blake> The planning of tanks can be

very detrimental to all those around the planner, it makes for

such entertaining day dreaming/"spacing out"! If only

we put as much planning into work, relationships, etc...

<Exactly, could you imagine?> The thought process on the

Dolphin was that I could throttle it back using a gate valve

without harming the pump. I was considering having aprox.

1000-1200gph through the sump. <You could do this, I would

just choose a smaller, cheaper to buy and operate pump.> Are 2

in. drains necessary? <Even with this flow they will be if you

want two drains with either one being able to handle the entire

flow. A 1.5' drain is only reliable for 750 gph or so.>

The Herbie method of overflow only uses one of the throughputs

and the other is strictly a safety measure. <Ah yes, I am

familiar with the method, not the name. I apologize for not

catching this in your previous email. While many use this method

with some success, it is still not a good idea in my book. Taking

an overflow and restricting it to balance the flow will always

fail in time. I understand that is what the second drain is for,

but consider the real danger: By using this method a siphon is

created in the line that drains the water (many would argue there

is not, but that is a whole issue in itself). By siphoning a

1.5' line can handle 1200 gph+. The issue comes in when this

line fails. The remaining drain is now either expected to drain

this flow gravity fed (and it won't) or counted upon to

create a siphon of it's own. This just too risky for the

floor/walls in my house! > I travel a lot and want as many

safety checks as possible. Can you recommend a pump that may be

more appropriate? <I personally like and use the larger Eheims

in such applications, there are other great pumps out there:

Iwaki, PanWorld, even a small Reeflo just to name a few.>

After reading Anthony's book "Book of Coral

Propagation"(great read by the way), I've decided to use

my old Coralife 220 skimmer and also upgrade to a MSX 200 (he

recommended having 2 types of skimmers). Additionally, I am

trying to plan plumbing a 5 gal. bucket of sand for a deep sand

bed underneath the main display(unlit) and only using a 1/2 in to

1 sand bed for the main display. <Sounds like it will be a

great setup.> And oh yes, I love the idea about shaded areas

and the aesthetic possibilities. Hopefully, I can find home for

some softies and different types of bio topes in the same tank.

<A matter of researching re compatibility.> Again, thanks

for the time and help. Thanks, Blake <Welcome, Scott

V.>

Tank Overflow Design 9/1/08 G'day WWM

Crew, <Ben> I have a 1500 litre 15mm thick glass tank

(currently empty, upgrading from my 46 gallon) with no overflows

and thought I already knew what I was going to do for overflows.

I have an Iwaki MD20RX pump that will return about 3000 litres to

the display tank. I will be using 2 x Tunze 6301 pumps for

circulation, so the Iwaki is purely to return water to the

display tank and supply my OctopusTDNW-300-6530 Recirculating

Protein Skimmer via the overflow with about twice the tanks

volume every hour, which should be perfect. My idea was to have 2

vertical corner boxes each with a 1" drain with possibly 1

extra 1" drain just for insurance. I thought I would read a

few Q&A's on WWM to see if this is the best way to go,

and haven't read anything too positive on this set up, most

articles I have read are suggesting a box mounted top centre

running lengthways, but I can't find anything reliable on the

net as to how best to build this type of set up. <There is

nothing wrong with the vertical boxes. Most the dissention you

have read about is due to the throughput size that these types of

boxes are usually sold with, they are simply too small. Your tank

would fall into this category with dual 1' drains, it will be

dangerously close to the capacity of these. Having the backup

will be helpful, but if you are starting from scratch you might

as well go larger, 1.5'. Another consideration re the

overflow type is the fact that many tanks use tempered glass on

the bottom pane (cannot be safely drilled). You will need to

check with the manufacturer to see about yours, if it is

tempered, a through the back overflow will be your choice.>

Would it be best to make an internal box from glass or acrylic,

with 3 or 4 1" bulkheads, if so what would be the best way

to attach this to the tank? I've read that there isn't

really a good way of bonding acrylic to glass, so would I be

better off making something from glass? <You could use glass

if you wish, nothing wrong with that. You can easily use acrylic,

building a back panel on the box. Then you can drill the box to

match the throughputs in the glass and use the bulkheads to hold

the box in. Just pay attention to where your gaskets go! I highly

encourage you to try the acrylic route if you are at all handy

with DIY projects. It will make the box removable and once you

learn to work with acrylic you will open up a whole world of DIY

equipment options for yourself.> What do you suppose the Ideal

length for such a box would be? (I have an 8 foot tank). <Up

to the whole length of the tank if you wish! Really, a foot or

two is more than plenty, there is a greatly diminished return re

surface skimming after this length with this amount of flow.>

I hope you might have some suggestions or be able to point me in

the right direction. Thanks again for your help as always, Ben

Adelaide, Australia <Welcome, have fun with this project!

Scott V. in Monterey, Ca today.> Sump/Overflows

8/29/08 Hello again Guys, thank you so much for all the

information you have given thus far. I have learned a lot from

reading the FAQs as well. I have some thoughts and would like

your opinions. I've decided to build my own sump out of a 15g

glass tank; this is the only size that will fit in my stand. I

read the info about the use of foam rubber to seal the baffles in

place and will try that. <It is a good way to start out, you

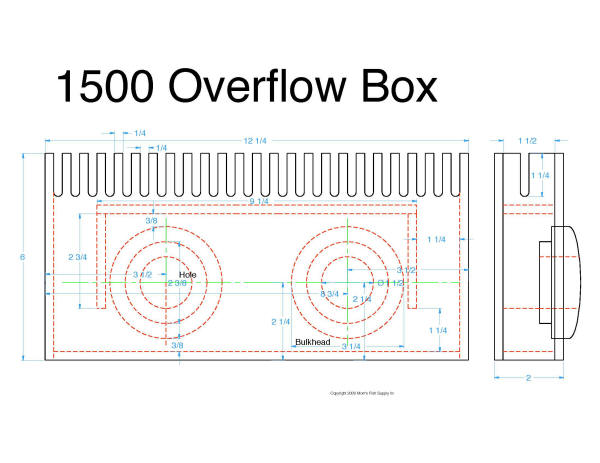

can adjust if needed.> In your previous response you said to

use two 1.5" drains, looking at the Glass-Holes.com site I

saw the one rated at 1500GPH. I assume this is the one you were

referring to correct? <It qualifies as one. Any 1.5' drain

can work, even without a box. It just depends on what you want to

see in your tank. Do a quick Google search on overflows, you will

find a few to choose from.> It seems to me like overkill for a

46g display tank, which will give it a turnover rate of about 32x

per hour. Then again the more turnover the better right? <More

flow is good within reason. You do not want to run ANY overflow

to the limit. Ideally an overflow will be run to 50% or less of

its capacity, with multiple drains. Overflows can plug, having

redundancy in place keeps the water where it belongs.>

Here's the plan: 1500GPH overflow, 15g DIY sump, skimmer,

Knop "C" reactor, plus the return pump and plumbing of

course. I was thinking of an Eheim, I need it to match or

outperform the overflow right? What do you think of this? Am I

missing anything? <Eheim is a great choice, as for flow, see

the above.> I'm also going to the LFS to scope out their

setups for plumbing ideas. Thanks again guys for all you do.

Craig

<Welcome, Scott V.>

|

Protein Skimmer, sel. refugium plumbing

mostly 8/13/08 Hello Everyone,

<Ramon> I have a couple of questions about a protein

skimmer for my system. <Ok> My tank is a 55 gallon

(not drilled), with a 2 inch sand bed (adding 2 more

inches) and 2 15 gallon Rubbermaid containers. 1 is a

refugium and the other is a sump. <Nice> I am

planning to upgrade my refugium and sump with two 20 long

or two 30 gallon drilled tanks, I also want to know if I

stay with my 1 inch gravity return line how large should I

have my feed line drilled? <For what you can get

practically through this one line, I'd run all

consecutively through both sump, refugium... first the

'fuge... I'd make two overflows if you're

drilling... run one each independently to...> How far

down from the top and should it be level with the return

line? <Two inches and yes> the platform is only

18"w by 24"l by 13 1/2"h which the bottom of

the platform is sitting level with the tank, it would

gravity feed to the main tank, so I was wondering which

tank would be my best bet? <The bigger the better> I

plan on staying with my 55 for a long time and not

upgrading. it will house some fish with mostly button

polyps, mushrooms and leathers. I was wondering if the Aqua

C Urchin series would work for my set-up? <Of a

certainty, yes... a very good choice> or should I get

another type of skimmer? It will sit in the sump and budget

is tight as always. <Save up...> Thanks Again, Ramon

Ortiz Tampa, FL <Bob Fenner, Kona, HI>

Re: Protein Skimmer, actually sump/fuge

plumbing 8/14//08 <Howsit?> I was

wondering should I have a pump for the fuge and one for the

sump or one for the fuge and "T" it to the sump?

Or just run a line from the sump to the fuge and then to

the tank? <I would definitely run two pumps... but have

an "equalizer line" (pipe and through-puts) twixt

the two sump/refugiums... lest one overflow or return

be/come out of balance. BobF>

|

Bulkhead Placement/Drain 7/7/08 Hello,

<Mark.> After much searching on your site I still

cannot find the answer to my question. I have a 38 gallon

tank that I would like to have drilled. I am however not sure

of where I should have the hole for the bulkhead drilled. I

will be having the back drilled as the bottom of the tank is

tempered glass. <OK> I am thinking that one 1"

bulkhead should be sufficient, for this size tank, as it will

not be a reef tank. I do need flow but not tons as it is for

seahorses. I was wondering if you could help me out with the

placement of the bulkhead. I will be running and external

Durso. I really do not want to use an O/F but was thinking

instead of using a spa screen which you can see in the

attached picture. The spa screen will be flush against the

wall. I can do an O/F if I have too. <An overflow box is

not a necessity. Although the screens you have are very nice,

do be aware that these will drastically restrict flow through

a gravity fed drain and will of course clog very

quickly/easily.> Please help me in figuring out if the

1" bulkhead is large enough and where to place it in the

back wall of the tank. <First off, do not plan to have too

much flow through this. A 1' drain will give you 300 gph

reliably, count on half this with the strainer (brand new and

clean), seriously! As for the height/placement of the

bulkhead, it is hard to give you an exact number, too many

variables, the amount of flow, plumbing on the other side of

the bulkhead, buildup on the screen etc. Fact is you can run

at 50 gph and have a water level right in the middle of the

screen, kick it up to 150 gph and you will likely have the

entire screen submerged. This is the advantage (one) of using

a box. It will preset your water level no matter what the

flow (within reason). Consider placing you bulkhead a few

inches down from the desired water level and then use a

simple PVC elbow to control the water level. It can be left

to swivel in the bulkhead, making adjustment easy. If your

water level is still too low a short length of pipe can be

added to the elbow to raise the level. Screen/gutter guard

can be used to keep things out.> My apologies in advance

for the rather foolish questions but this is all a new way of

plumbing for me, and I am learning as I go. I have asked many

people, but have gotten so many varying answers I thought it

was time to head for the best. Thank you in advance

Mark

<Welcome, Scott V.> |

|

Re: Bulkhead Placement/Drain 7/9/08

Dear Scott, <Mark> Thank you for such a quick reply.

<Very welcome.> I understand what you are saying, The

flow I am looking for is between 200-400 GPH. So in order

to kick up flow should I go with a slightly larger bulkhead

say 1.5" or 2" or have two 1" bulkhead holes

drilled into the tank. <Two 1' bulkheads will work,

I would opt for the 1.5' though.><<Mmm, RMF

will (not rudely hopefully) butt in here and say he'd

definitely have two (or more!) 1.5" ID through-puts...

redundancy is a VERY good idea here... as one never

knows... when a screen/intake will be occluded, blocked to

an extent, NOR if/when one will want to upgrade their flow,

overflow>> If I should go the route of two 1"

holes drilled for a 1" bulkhead what should their

placement be? <Still too many variables to know for

sure, best to make it adjustable or try it in a throw away

container first to figure out where your water level is

going to be, relative to the bulkhead, using your pump at

the same head pressure it will see with the tank. Even then

it will change as crud builds up on the screen.> One

last question I would not mind putting an O/F into the

aquarium, but am unsure where to buy/find an O/F that is

out of glass and not acrylic, or how to make one or have

one made. <They are fairly straightforward. A bit of

acrylic and solvent (like Weld On 3), add a saw and you

have all you need to make your own. Another alternative is

to have pieces of glass cut and silicone into the tank to

form an overflow box. If you wish to buy there are several

sites; WetDryFilter.com, AustinOceans.com and

Glass-Holes.com (my site to disclose) are three sites that

offer through the glass overflows.> Thanks again for you

help it is much appreciated. Mark <Welcome, have fun,

Scott V.>

Re: More Re: Bulkhead Placement -- 07/10/08

>Rude? No way!! This is a very valid point we both know

I am educated on, shame on me for not including the

statement. Redundancy is a key aspect of any overflow

system's reliability. Thank you for adding this! Scott

V.< <<Mmm, RMF will (not rudely hopefully) butt in

here and say he'd definitely have two (or more!)

1.5" ID through-puts... redundancy is a VERY good idea

here... as one never knows... when a screen/intake will be

occluded, blocked to an extent, NOR if/when one will want

to upgrade their flow, overflow>> <Thank you

Scott. BobF>

|

Aquarium Setup and Pump/Overflow Questions 6/25/08 Hi

there, <Hello.> I am in the planning of 40 gallon breeder

with external coast to coast ( I like the setup and that

there's no space taken inside my tank) that goes to a 25

gallon sump. My plan is to keep softies and SPS corals with

little LPS (if I cannot avoid the temptation @ all). Anyways, I

am planning to follow same system as

http://www.reefcentral.com/forums/showthread.php?s=25431f8f03640480f5d7cce63c204925&threadid=1310585&perpage=25&pagenumber=1

with 1 inch drain pipes. To give you the brief summary,

there're two 1 inch pipe draining water but most of the work

is being done by 1 pipe (3rd pipe is for fail safe). I had some

questions over here: 1. I am planning to bring water back from

sump to display via Eheim 1262. It's a simple return from

bottom that will split into 2 pipes (I need the size

recommendation from you) and will be connected to ¾ or

½ inch LocLine (as you recommend) over the top. The

pipes will move water upwards about 5 ft. Do you think this will

work? <Well, yes and no. As far as the overflow, this employs

one drain as a full time siphon, with the second gravity fed

taking a bit of flow. The third is a gravity fed backup. The

problem is that a gravity fed 1' drain can handle just a bit

more than 300 GPH. The siphon 1' drain can flow 900 GPH or

so. What happens when (not IF in my experience) the siphon to

fails? The other two drains (one of which already had part of

it's flow used before #1 failed) cannot handle the flow.

There are many of these 'overclocking overflow' designs,

all end up relying on a gravity fed drain for a backup. The

reason is that the gravity fed drain is far and away the most

reliable. If you have enough gravity fed backup capacity to

accommodate the flow of the siphon fed drain if it fails, why

have the siphon drain to begin with? It is an overflow design

that does work most of the time, I am just not a fan of it after

many (hundreds) of hours building and actually flow

testing/trouble shooting overflows. In regard to the return, the

issue with bringing it through the bottom of the tank is the

potential for sump flooding. In the event of a power outage the

water will siphon or simply drain down to the level of the sump

output. Even if the return comes through the bottom and you bring

it up, you risk the possibility of a leak in the line somewhere

(LocLine is NOT watertight) leading to the same problem. All of

this seems paranoid, but this stuff does happen, if you plan on

having the tank for any length of time you will likely end up

experiencing these events first hand.> What size returns

should I use? <A few ½' or a single

¾'.> Can Eheim handle such load and is it fine

for this kind of setup for optimal working of sump (which may

contain refugium to it too)? <Yes, this is my personal

favorite return pump.> 2. I am planning to add 2 Maxijets 1200

(modded) and two Koralia (need size recommendation) to move water

inside the aquarium too. Do you think it's sufficient for

SPS? <Yes, definitely. You will not need so much flow, either

the MJ mod.s (another personal favorite) or the Koralias (fours

would be my choice) will be more than enough for a SPS tank this

size. > Do you think water will get too hot? <It may,

especially with the MH, time actually set up will tell.> I

live in Seattle so it really is not that hot over here except for

occasional heat wave. <The occasional heat wave is what can

get you.> 3. I am planning to add 1 250 WH Metal Halide with 2

VHO on the aquarium as light? Is the light sufficient? <Oh

yes, quite.> Other questions may come up but I need your

recommendation on #1 and #2 so that I can start ordering plumbing

stuffJ <OK> Thanks Ghazni <Welcome, have fun setting up,

Scott V.>

PVC Size/rate of flow 6/16/08 Hey

All! I hope your Saturday is going as well as mine! <Hello, it

is/did!> I am sorry to bother you with this, but I cannot seem

to find the answer myself. <No problem.> I am in the

plumbing stages of my 150 setup -- it will be plumbed through the

wall into a 120 refugium and a 55 sump. Can I tee the 2 x 2'

drains from the 150 into a 3' to go through the wall or

should I use 4' PVC instead? <3' will yield enough

flow to handle dual 2' drains.> The answer will then allow

me to determine how far from the wall the stand needs to be. I

would hate to go with the 3' only to find it to be too small,

and although it may be easier to just run both 2' drains

through, I'm thinking that on pipe through will look much

cleaner. <Your choice, dual 2' lines may very well be

easier to handle and setup.> Thanks in advance for your help.

I have been an avid reader of the FAQ's for several years --

the help all of you have provided me (and countless others) is so

very much appreciated!!!! <Thank you very much for the kind

words. You're welcome, always a pleasure to help, Scott

V.> Drains, Returns and Closed Loops, OH MY!

6/1/08 Hey Guys! <Brian> So here's where I am

at and need some plumbing help. I have a 120g (48.5x24.5x24) AGA

with center overflow that has a 1.5" drain. The tank is also

drilled with 4 1" bulkheads along the back. I originally was

going to use just the 1.5" to drain to the 40g breeder sump,

and 2 of the back holes for returns with the other 2 for closed

loop intakes, but after much reading on your site I think it

might be best to change that train of thought. So here is where I

am at, and would love to hear your thoughts. <Okay>

1.5" drain and the 2 outer 1" to drain into sump. That

would put approx 2200ish gph into sump. <Uhh, no... about half

this at most> So first question is with 5' of head, what

should my return pump be rated at to handle that. <I'd

stick with about 1,000 gph maximum calculated> Internal,

external doesn't matter. I would run 1" return line back

up T'd off to separate 20g fuge(this will gravity feed back

to sump return area). The 1" return line would T off again

up near tank and drop back over the top into tank. The other 2

1" drains would T together up to 1.5" to feed into Dart

pump for closed loop. I would run the dart up through a OM 4-way,

2 returns would come up over the top to the front corners with

loc-line, the other 2 would come over the back of the tank, run

along the very back inside the tank to the bottom middle on each

side and come back up through the sand with more loc line to

generate flow back up. I have to run the lines through the tank

as the bottom is tempered and can't be drilled. The goal is

to have no powerheads anywhere in the tank. <Will, can be made

to work.> I am sure there is something I'm missing in

here, so any help is appreciated. Thanks, Brian <Just

"missing" the estimate (of probable gravity/drain feed

from the 1.5 and 2-1" lines) and need to consider the return

in turn... all else reads as fine. Bob Fenner>

|

Bulkhead And Non-Standard Hole Size

Question -- 04/22/08 Hi Crew, <<Howdy,

Paul>> I'm going to try and make this issue short

and sweet because I know how busy all of you are.

<<Ah, no worries mate>> I couldn't find

this issue when searching through the site. <<Mmm,

well'¦guess there will be one after this

[grin]>> I am setting up my new 110g tank but I have

one problem. The tank has a 1" overflow hole drilled

in the bottom of the tank that was used for a wet/dry. Only

1 hole and it was previously capped off with a

bulkhead/pvc/cap. <<I see>> It was covered with

LS so it was not being used. I had to cut off the bulkhead

in order to move the tank out of the stand because there

was 5 inches of pipe hanging down. Now that I have the tank

set up I am going to cap off the hole. I was going to do

the same thing as the previous owner by using a bulkhead.

<<Hmm'¦do you want to keep this hole/have

the hole available for use at a later time? If not, maybe a

glass 'patch' silicone over the hole would serve

better. A double layer of inexpensive 3/16' float glass

from your local Lowe's/Home Depot/Hardware Store will

do the trick (they will even cut it for you). Just cut a

pair of patches to overlap two-inches beyond the perimeter

of the hole'¦center the first patch and secure to

the bottom glass of the tank with silicone (apply enough

silicone to fill-out/adhere the entire surface of the

patch)'¦next, apply a thin layer of silicone over

the entire surface of the first patch and then lay/secure

the second patch on top of this (use a small weight to hold

all in place). The resulting 'laminated' 3/8-inch

patch will be quite strong and water-tight'¦and

nothing will be sticking out the bottom of the tank to

interfere with the stand and equipment below>> To my

amazement, the hole opening is 1.5". The old bulkhead

barely fits in the hole and is also 1.5". <<Can

be found...though generally not from an 'aquatics'

source>> As you can probably see I can't find a

1" bulkhead that will fit into a 1.5" hole.

<<Will probably take a little searching of industrial

fittings, but they are out there. A good place to start is

USPlastics.com>> They all require at least 1 5/8.

<<Most of those available from hobby sources, yes (or

even a 1 ¾' hole>>> I tried to

enlarge the hole using 50 grit sandpaper.

<<Mmm'¦save your strength>> After 2

hours I didn't feel like I was getting anywhere and I

was extremely tired. <<Indeed>> I'm looking

for options. <<A Dremel tool and a diamond-grit

bit>> I thought about buying a 4"x4" square

of glass and silicone it, keep grinding away to enlarge the

hole, or maybe you know of a 1" bulkhead that will fit

into a 1.5" hole. Any thoughts on the best solution?

<<All three are viable options'¦but the

glass patch (as I outlined) would be the easiest and

'cleanest' fix, in my opinion>> The hole will

be covered with LS when the tank is up and running. Thanks

as always. Your input is invaluable. Paul <<Always

happy to share. EricR>>

Re: Bulkhead And Non-Standard Hole

Size Question - 04/22/08 Thank You for your response.

<<Quite welcome>> I was thinking the glass

patch would be the best solution as well but I wasn't

sure if I was going to run into any structural problems

using a thinner piece of glass with all the weight on top.

<<Easy enough to 'build-up' the patch to

match the thickness of the glass on the tank's

bottom>> I can get glass pieces from a local glass

store. Would it be better to get 1 piece of 3/8 or is

having 2 pieces siliconed together stronger. <<The

single piece of thicker glass will work'¦but a

laminated patch 'will be' stronger/more

durable>> I will definitely go the glass patch route

though. <<Excellent choice>> Thank You. Paul

Kelly <<A pleasure to assist. Eric

Russell>>

|

Bigger Overflow Holes 4/9/08 Hello Crew!

<Hello John.> Thank you for all that you do. You are

appreciated and admired by aquarists and fish everywhere!

<Thank you for the kind words and encouragement!> I have

one quick question. I have been reading, over and over, that in

many instances, the diameter of the overflow holes on the A.G.A.

MegaFlow systems [factory-ready] is not large enough. <No,

they are not really large enough.> Can you/would you name a

glass aquarium manufacturer, who makes standard-size/pre-drilled

(reef-ready) tanks that have BIGGER diameter holes than those

found in the A.G.A. tanks? I've done MANY web searches for

this information, and I keep coming up empty. <Most tank

manufacturers will drill more/larger holes for you, for an extra

fee of course. I have particularly found www.aqueonproducts.com

(formerly AGA) to be great with their customer service. No long

waits on the phone! Just give them a call and explain what you

want, they will help you.> Much appreciated. Have a great day.

John D. <Welcome and thank you. Have a great day also, Scott

V.> Combining Overflows/Refugium Substrates 2/26/08

Greetings WWM Crew, <Hello Bart.> I have always enjoyed the

hours I have spent reading on your site and the valuable info you

provide. For this I offer my thanks. <Thank you.> I have a

few plumbing questions for you regarding a system project I am

undertaking. After three years of successful reef keeping in my

72 gallon bow-front I have acquired a pre-drilled AGA 120 and am

making the switch. I am especially excited to do away with my

siphon overflow (no major mishaps...Just lucky I guess). <I

hear you my friend!> I will keep a variety of LPS corals on

about 120 lbs of liverock and stock fish very lightly. The tank

is pre-drilled with two Megaflow overflow chambers installed.

They have the standard 1" drains with Durso standpipes and

¾" returns. I understand from my research here

that these are smaller than is to be desired, but my thinking is

that I can get healthy water flow if I add some big powerheads in

the tank and take care of filtration and skimming in the sump

with the 12 or 1300 GPH I will get from the twin drains. Is this

reasonable to assume? <I am sorry, but no. These are smaller

than to be desired, a 1' bulkhead will only flow around 300

GPH safely, giving you around 600 GPH total draining

capacity.> My plan is to place a 50 gallon sump in the

basement, directly below the tank. If I were to combine the two

1" drains into one 2" pipe, will my drains slow down?

<This will work fine, the 2' has about 4-5 times the

draining capacity as a 1'.> I'm thinking it would be

easier to send one pipe through the floor than two. The sump will

be a simple design and house a skimmer (not selected yet)

followed in line by a refugium. The return pump will be an IWAKI

MD70RLT which should be able to handle return flow approaching

1400 GPH at the required head. <You will want to choose a

smaller pump.> Since the combined flow to the sump directly

below the tank should be around 1200 GPH, would this be too much

flow for a refugium housing only Chaetomorpha? <No, that is

fine for the Chaetomorpha, but you will not be flowing this

much.> I am considering a sump with no substrate because I

have heard that the substrate can become a nitrate factory. This

is confusing because I have also heard that Deep Sand Beds are

denitrifiers. What are your thoughts regarding refugiums without

substrates? <I like and use the DSB method. Substrate can

become a nitrate factory when it traps excess detritus, usually a

trait of large grain substrates. The use of fine substrates will

not be an issue and will benefit your system with proper water

flow, which you will need even if you leave the refugium bare

bottom.> My plan is that the Refugium and the skimmer would be

the ONLY filtration in this tank. <And the live rock in your

display.> I thank you in advance for any help you can offer.

Keep up the good work! Bart <Welcome, will do. Scott

V.>

Doing an Overflow "Calfo" Style

2/23/08 Hello Crew, <Good evening.> I've been

reading and searching on WWM for my question to "Calfo"

style overflows but can't seem to find the answer. I'm

installing an overflow in the back of my 90 gal tank which has

been drilled for two drains. Both drains are using 1 1/4"

PVC attached to 1" bulkheads running to the sump. <OK>

Due to space limitations where the tank is located the bulkheads

for the drains are reversed ( flange on outside of tank) allowing

the plumbing to fit closer to the tank. Thus this places the

longer threaded end of bulkhead inside the tank. <Not a

problem.> The bulkhead and PVC down elbow protrude approx 3

1/2" into the tank. If I install a "Calfo" style

overflow obviously it will have to be at least 4 1/4" wide

to allow for removal of the elbow if necessary but the question I

have is how deep does the overflow have to be? How much water

should be inside the overflow below the level of the drain

bulkhead? <You will want the inside bottom of the overflow to

be at least 1 ¼' from where the water will enter

the elbow in this case. This will allow unrestricted flow into

the elbow. You can go deeper if you like, but it is not

necessary. You may also be able to trim the bulkhead and elbow

down a bit to get the width down a little.> I was going to

purchase an overflow that I could drill and attach to the

bulkhead fittings but after some consideration on the hefty

prices of the commercially available overflows, I'll make

mine. <I do sell overflows and do always encourage people to

make their own whenever they are comfortable doing so.> Any

input on design considerations for my tank is greatly

appreciated. <It sounds like you have the right idea and a

good plan. I will give you one tip from experience: If you do not

go all the way from one side of your tank to the other, do be

sure to leave enough room between the overflow and the side to

fit in a magnet cleaner! It is all the small things that make

life easier.> Keep up the outstanding support. <Will do,

thank you, Scott V.> Overflow Options 2/15/08 Dear

crew, <Hello James.> I currently have a 300 gallon acrylic

tank. 96x24x30 with two overflow boxes, 5x6 inches in each

corner. I was planning on putting 2in bulkheads in each, but I

can't fit the 2in Durso standpipe in that narrow box.

<Bummer.> I've trimmed the elbow and tee down so the

standpipe now barely fits in, but I would have to drill the hole

very close to the seam. I'm trying to get 3000gph through the

tank. Question#1 Should I get rid of the standpipe so I can keep

the 2incn drains in the overflow box fairly centered and away

from the seam. < With this much water being moved it will be

quite noisy without some sort of standpipe.> Question#2 should

I use the overflow boxes for the 11/2 returns and just drill the

back for 2-3, 2inch drains? <If you are set on running 3000

gph through the sump then this is your best option.>

Question#3 If I drill the back, how far below the top seam would

I have to drill for the 2inch bulkheads. <I assume you intend

to drill the back inside the overflow box? This will allow you to

fit an inverted elbow inside the box to quiet things down. As for

height you will want the top of the bulkhead to be a few inches

down from the top of the overflow. Go too far down and you will

hear the water falling inside the overflow. If you planned on

drilling outside the box your height will depend on how you plan

to set the drain up. If you just plan on running an elbow inside

the tank you should drill fairly close to the top, but leave at

least one hole diameter between the hole and any edge. If you

plan on building a box for the overflow, then the same

recommendations apply as above for the built in boxes.> I

would greatly appreciate your advice and opinion on this matter,

thanks james <Welcome, good luck, Scott V.>

Horizontal Overflow 2/8/08 Hello! <Hello

Mike.> I have a 75g tank I would like to use with a sump setup

for an African Cichlid tank.. <OK> I would like to try the

"horizontal overflow", however, I'm not having a

whole lot of luck finding any "standards" to go by for

what actually "works best", such as, length, width,

height, how far below the waterline you should place it, optimal

bulkhead depth, (2) 1" bulkheads, or (1) 1 1/2"

bulkheads? <Nor will you'¦there are no such

standards. Each individual application is entirely

different/custom. The size of the box/weir will be dependent on

how big you want it. As far as waterline it may take some trial

and error. This aspect will depend on the size of the box you

build and the flow running over it. If you run 1000gph over a

5'X5' box the water level is going to be higher than a

5'X10' box. The bulkheads are again totally dependent on

your planned flow through them, but larger is usually better. As

far as bulkhead placement, I would recommend you place the

bulkheads as high up in the box as possible. If you place them

too low you will hear the water as it falls from the top of the

box down to the bulkhead's level.> If you could point me

to some useful resources to help me in my planning, I would

appreciate it.!! <I build (and sell) a similar product to

this. You can view my installation instructions in the link below

to get some ideas regarding placement and size/flow. The general

idea for your project is the same.> Thanks for your time (and

help)! Mike <Welcome, have fun, Scott V.> http://www.momsfishsupply.com/overflowinstallation.html

100g Tank Transit Volume/Overflows 2/4/08

Hi Bob, <Hello Lewis, Scott V. with you.> The website is

great but I was wondering if you could give me some advice about

my current situation. <OK> I have a 100g tank given to me

for free that was drilled with 2 x 1 inch holes at the waterline.

I have a 500 GPH pump returning water from my sump, but because

of the head, this is about 250 GPH. I would like a reliable

method (ie. power cut tolerant) of draining water from my tank to

my sump, without flooding. I know you have recommended 6 x 1 inch

holes for a 180g in the past, but I can't drill my tank. I

currently have a siphon set up, controlled by using a tap on the

32mm drain, but this is not practicable long term, as in the

event of a power cut, my tank would drain about 15g into my sump

with a total capacity of about 10g. So, which parts of my setup

need I change/add? Many Thanks in advance! Lewis <Your issue

here is the transit volume, that is how much water is above the

overflow, in the lines or gets siphoned out via your return line

when the power is off, not the overflow itself. You may be able

to lessen this by positioning the return line output directly

below the water level in your tank or drilling a siphon break in

the line. The transit volume will always be there, as a certain

percentage of the tank volume, so it is likely you will simply

need a larger sump for a tank this size. A note on the overflows,

your 2X1' will easily handle the flow you are running and be

far more reliable than the siphon type. Welcome, good luck, Scott

V.>

|

Re: Size of Water Pump 2/3/08... actually

size/drain flow rates, referrals... Did I mention I

have 2 intakes and two returns <Yes you did, unless they

are larger than 1' you will need to throttle back the

PS4, or go with a smaller pump, Scott

V.><<Scott... refer this person... They need to

read... comprehensively. RMF>>

Re: Size of Water Pump 2/4/08 Will my

tank drain about 1200 gph?? <No, more like half this

with two 1' drains, Scott V.><<...>>

Re: Size of Water Pump 2/4/08 Found something online

that is identical to my overflow kit. It says it drains

600gph. <Not safely with a 1' line.> All-Glass

Aquariums MegaFlow Overflow Accessory Kit * For efficient

water collection and replenishment for all All-Glass

Overflow Aquariums * Simple to install - no tools required

* Easy to clean Plumbing kit designed to fit pre-drilled

MegaFlow and Corner Overflow aquarium systems for efficient

water exchange. Requires no tools or glue for convenient,

easy assembly. Includes 1" and 3/4" bulkhead

fittings, adjustable "J" drainpipe, return pipe

with flexible nozzle, 90° elbows, and intake

strainer. Handles a flow-through rate of 600 gph.

http://www.drsfostersmith.com/product/prod_display.cfm?c=

3578+10090+12079+12078&pcatid=12078 This tells me that

my tank should drain 1200gph?? AM I right?? <You are

correct that it tells you that, but the statement is wrong.

A 1' drain will not flow 600gph without siphoning, no

matter how many manufacturers say that it will, and many

do. A 1' will drain over 600 gph with a siphon, but

there is many issues doing this. First is noise: unless you

run the drain exactly at full capacity, you will have a

cyclical flushing noise (very loud) as the drain outruns

the pump and then water fills above the drain until the

siphon starts again. All of this assumes that the siphon

does in fact start every time. To combat this you must

match the pumps flow exactly to the drains flow, a

balancing act that you will lose very quickly, overflowing

your tank. I would use three of your holes as drains,

leaving the fourth for a return. The three will give you a

safe, quiet, gravity fed 900 gph, more than enough flow

through your sump. As far as the return, one 1' line

coming off a pump is more than enough to handle this flow.

You can stick with the pump you propose and throttle it

back, although I do invite you and try it with two drains

(pvc is cheap) and see for yourself, you will be a convert!

Good luck, Scott V.>

Re: Size of Water Pump 2/4/08 <I

have combined the bombardment of emails sitting in my inbox

into one email for the sanity of all involved.> My

overflow accessory kits (2) are made by oceanic. They are

reef ready model # is 70009. The pipes are about an inch

and a half but at the bottom they taper down to 1 inch

which are then connected to I believe a 3/4 bulkhead. If my

flow is only 600gph. Is this enough water flow to convert

it into a saltwater tank or reef tank?? Is there enough

water movement @ 600gph?? Also, should I look at other

water pumps besides the Poseidon or maybe an Iwaki?? Thanks

again. How do I connect my 2 dual nozzle spray bars off one

return in the over flow box. Do I use flex tubing of some

sort with a tee?? Is this enough flow for a salt water

tank??? the 900gph using the 3 holes for drainage as u

mentioned?? Which pump would u recommend?? thanks again!

When I build my sump, it will have 2 independent holes in

the cover for the drain pipes at 1 inch. Should that make a

difference in the GPH??? <All of the above is answered

time after time either by our previous correspondence or on

WWM, the site you are instructed to search before writing.

Scott V.>

|

|

Question about tank

integrity re: drilling -- 1/28/08 Dear Crew,

<Brian> Hope all is well with you fine ladies and

gentlemen. Once again, I find myself seeking the advice of

the sea water sages. I know a few of you have prior tank

building / fabricating experience, and wanted to run this

by those who may have more experience than myself. I've

drilled the back panel of my 75 gallon, which I believe is

3/8 inch glass, in preparation for the overflows to the

sump, and intake and outputs for the closed loops. 6 holes

in total, 5 are to accommodate 1.25 inch bulkheads, and one

for a 1.5 inch bulkhead. <Okay> My question is re the

integrity of the panel once filled with water. I understand

people drill their tanks all the time, and even I admit

that the process was much easier than I thought it would

be. However, I read many threads on various forums with

people stating their tanks have failed usually with cracks

radiating from near the location of the holes. I am

wondering, would it would be advisable to silicone a few

pieces of glass length wise to the back panel in order to

provide stability, and reinforce the weakened panel? I was

thinking of adding three strips to the back of the panel on

the long dimension (48"). Will I gain any added

stability to the panel by doing this? Or rather, a waste of

time? <Mmm, not an idea w/o merit... do look up the term

"Euro-bracing" for ideas on how I would approach

this> I appreciate your input, and await your advice.

Cheers, Brian <Mmm, a few more statements, related... I

encourage you to make sure there is no/little stress from

the plumbing "hanging" from the through puts

(VERY important) and that the bulkheads themselves are well

seated (with a smear of Silastic on the inside and outside

faces, including on the gaskets) and that these are

securely tightened... once again, to distribute the force

about their perimeters... Bob Fenner>

Re: Question about tank integrity re:

drilling 1/28/08 Bob, <Brian> Thank

you for the swift reply. After researching "euro

bracing", I've decided that it would indeed be in

my best interest to beef up the integrity of the tank. Will

take the suggestion to heart, and visit the local plate

glass shop for some reinforcing strips. <Ah, good>

Also, I wanted to thank you personally, Bob. When I was new

to the hobby and wandered into my LFS to purchase a tank

and some fish a few years ago, after speaking with me for a

few moments, the clerk told me that there was only one

piece of equipment I would need to start with. He then

proceeded to walk me over to the hobby literature section,

pick up a copy of "The Conscientious Marine

Aquarist", and advised me to go home and read it over

several times, then come back when I was ready to go. To

this day, I still find myself referring to it for advice

and guidance. Both I, and my reefs inhabitants thank you.

<Welcome my friend> Next time you're in

Chesapeake Bay country, drop me a line and the beer and

crab cakes are on me! <Mmm, yummy!> Kindly, Brian

Rinehart <BobF>

|

Enough "fall" for Overflow 1/6/08

Crew, <Ben> Thank you in advance for you response. Before I

go hole sawing through my living room wall, I thought I better

run this by you. I'll try to ask this in a clear concise

manner, but bear with me. <OK, no problem.> I have a

240gal. "through wall" set up, as in the display with

stand & canopy is in one room, and everything else (sump

etc.) is in the garage behind it. My concern is that the sump

sits on a 30" high table and there might not be enough

"fall" for the return lines. I have no experience with

hydrodynamics, but do know that this depends on how much &

over what distance, so here are the specifics. I have 4 X

1.5" drains drilled along the top back wall of the tank. My

return pump is doing 2460 gph with my manifold configuration as

is. (I've tested it several times) The drains, however, will

only have about 10" of fall over a 10' span. Is this

enough to keep up with the pump? <Should be, 615 gph per

1.5' bulkhead.> <<Mmm, what re the horizontal run?

This may have a decided impact. RMF>> I'm thinking that

because I have some overkill on my drains, that I should be okay.

<The more the better.> I guess the question boils down to

how fast does water move downhill? <The problem won't be

the 10' drop (you are not siphoning), it will be the 10ft

run, that does decrease flow somewhat, but you will be fine

here.> I hope I made this somewhat clear... Any help would be

appreciated. Thanks, Ben <Very clear Ben. Sounds like you are

on the right track. Have fun setting up, it is one of the best

parts of reefkeeping, Scott V.> Re: FOWLR Setup for Messy

Eaters 1/4/07 Thanks Scott for the response! <Happy to

help Brian.> I was looking at drilling tanks and found that

drilling tempered tanks (by me) may not be the best idea. I'd

rather not have a glass "sculpture" in my living room.

(Maybe I can sell it off for millions as contemporary art?).

<The bottom is likely tempered. Do check with the tank

manufacturer if your back is tempered, chances are it is not. You

can overflow through the back too. If you find a buyer for such

art, please let me know, I have many old tanks I can bust up!>

I was looking at hang-on overflow boxes. Would these work in

conjunction with the LR to keep the water clean with messy eaters

in it? <It would work fine.> I understand these work by

suction, so it would be prudent to have 2. <Highly recommended

to have redundancy with these and any overflows.> Do overflow

boxes come with a GPH rating? <They should, but the bulkhead

the box uses on the backside is usually the true limiting flow

factor with these boxes.> How should I match it up with the

return pump GPH rating? <If you have two boxes, there will be

nothing wrong with matching the pump's flow at the head

height you have to the full flow capacity a box/bulkhead. This

will leave you with each box being able to handle the pump's

flow should the other box fail.> For example, should one be

higher than the other? <If anything, have the pump flow less

than the box/bulkhead can handle.> Or should I just use a

variable ball valve to balance everything out myself? <If you

get a larger pump than needed, you will need to. Don't try to

balance the flow right on the verge of what the box/bulkhead can

handle. Leave yourself some margin of safety for things getting

partially plugged.> Scott also mentioned a filter sock. Is

this just like what it sounds? A sock placed somewhere where

water gets forced through it trapping particulates? <Yes,

usually the overflow line is dumped into the sock hung on the

inside of your sump.>Thanks again guys! You've been very

helpful! Brian learning a little bit. <Welcome, keep reading

and learning, have fun, Scott V.>

Questions Regarding

Overflows'¦(Another Unrealistic Expectation) --

12/26/07 Dear Crew, <<Hello Brian>> Hoping this

correspondence finds all you fine ladies and gentlemen in good

health, and enjoying a happy holiday season. <<Mmm, funny

you should ask as I'm still getting over a rather nasty bout

with the 'crud' for the past 8-days '¦ Not how I

had hoped to spend my vacation...but happy nonetheless to be

starting to feel 'human' again. Thanks for asking!

[Grin]>> My question today is in regards to providing

adequate flow through a 75 gallon reef system.

<<Okay'¦and I'm sure you've already read

through our more than ample information on the subject>>

Rather than buying a grossly under achieving

"reef-ready" system, <<Hee-hee! I guess you

have!>> I've decided to go the route of purchasing a

standard 75 gallon aquarium and having a go at drilling it

myself. <<Goodonya mate! Not such a tough task if

you're a bit handy'¦just be sure you get a tank that

doesn't have 'tempered' panels where you plan to

drill! Generally, on a tank of this size only the bottom is

likely to be tempered. If purchased new, the manufacturer should

have any tempered panels labeled as such'¦but it

doesn't hurt to contact them to be sure, especially with

older/used tanks (assuming you can identify the manufacturer, of

course)>> After reading through the various FAQ's

regarding overflow plumbing, and seeing the high praise and

feedback that glass-holes.com have received, I'm inclined to

go with their 1.5 inch through-the-back overflow system.

<<Okay>> Per their website, they indicate that this

should accommodate up to 1500 gallons per hour. <<Hmmm,

looks to me like this setup features a single 1.5'

bulkhead'¦750gph is a more realistic expectation here,

as well as a much more manageable flow rate re noise/sump

plumbing simplicity>> For safety's sake, I'm

considering adding a second bulkhead/overflow to provide for a

backup in the event that a blockage should occur.

<<Redundancy can be a life saver...>> Since this is a

system that is not dependent upon a siphon for facilitating the

overflow, am I correct in assuming that any return pump should

work provided that the rate does not exceed the overflow

capacity? <<That is correct'¦the return rate will

match that of the pump rate'¦assuming, as you correctly

stated, that the overflow rate of the throughput is not

exceeded>> The way I see it in my mind, the rate of the

return pump would dictate the amount of water that would flow

over the lip of the box, correct? <<Correct'¦and

thus you are likely also aware the 'height' of the

overflow box helps in determining the 'running' height of

the water in the tank'¦something to be considered when

positioning the box>> Sorry if this seems like a silly

question, I'm just preferring to err on the side of caution

as I only plan on doing this once. <<No worries mate, well

understood'¦ Do be sure to plumb a gate-valve on the

output side of the pump to temper flow if needed>> Many

thanks for your collective continued efforts, Brian <<A

pleasure to help, do let me know if I can be of further

assistance. EricR'¦back with the living>>

ScottV chimes in: <The Glass-Holes.com kit mentioned

does indeed include two 1 ½' bulkheads. It is

actually the kit shown in the video on the same page. The

picture/listing is generic'¦I will remedy this. Sorry

for the confusion, Scott V., fellow crewmember and a partner in

Glass-Holes.com.>

Re: Questions Regarding

Overflows'¦(Another Unrealistic Expectation) --

12/26/07 Eric, Scott, <<Brian>> Many thanks for

the clarification, and again for the excellent advice. Cheers,

Brian <<Ah yes, I am glad Scott stepped in to

clarify/correct my perception of the "kit"...don't

need any added confusion. Good luck with your project.

EricR>>

Drilling overflows in AGA 12/16/07 Crew,

<Hello David.> I just ordered an Aquarium Glass Diamond

Hole Saw Kit from Diamond Tool King who advertises as one of your

sponsors. I already paid for the purchase through PayPal. Do you

know if Steve @ Diamond Tool King is legitimate? His prices are

excellent, which sort of scares me. I hope his being one of your

sponsors, or his advertising on your pages shows he is

legitimate. <No worries, the bits will work fine.> Here is

why I am ordering from him. I am setting up a reef tank starting

with a 120 gallon AGA tank. I keep collecting pieces and parts,

and reading and continually Reading and rereading. Sorry to say I

did not find out about your site until a few weeks ago. I have

now repeatedly read that the bulkheads holes are to small too

begin to consider the tank a "reef ready Tank".

<Unfortunately the case.> Yes I will, after tank aging, use

the tank principally as a SPS tank, with a small scattering of

LPS and even less soft corals. To date I have obtained two Iwaki

40RLXT's, Turboflotor 1000 with Ocean Runner 2700 pump for

skimming, Aqualight Pro with two 250-Watt 10,000 K and two

96-Watt PC's. I also have a Megaflow Model 4 Sump, which had

to be trimmed to even allow for the TurboFlotor. If I had known

that drilling bulkhead holes was not such a great task I would

have never gotten the MegaFlow sump. I might still replace it

with a glass aquarium and place the baffles where they will work

best. <Whatever it takes to suit your setup, drilling the

glass is fairly straightforward.> I do not plan on using the

Bio-balls that came with the sump so it might workout OK. I plan

on about 100-150 lbs Live Rock some thing from at least three

different areas. Probably large Fiji rock, Tonga shelf and branch

rock and some other exotic rock. Now for questions and

suggestions. I plan on cutting out the AGA overflow boxes and

plugging the small bulkhead holes with plugged bulkheads. Yes I

even footed the stupidly high price for two Megaflow overflow

kits. Learning can be expensive! <Learning generally costs

something, whether it be time or money!!> Anyway I plan on two

3 inch holes for 2 inch overflow bulkheads on the tank's back

wall, giving a space of at least 3-3.5 inches between hole edge

and tank inner wall. Top of 3 inch holes about 2 inches below

tanks glass cover ledge. <Sounds good, perhaps a little bit

lower. General rule of thumb is one hole diameter away from any

edge. Two inches down should be fine, but three will give you

that much more strength in the end. Good choice on overflow size,

plenty of capacity here.> The return locations I am not sure

of. With the tanks present setting viewing will be almost

entirely through front wall of tank allowing me free rein to

drill return holes in side wall which I believe would create

better turbulent flow possibilities due to the opposing flow from

returns at both ends of tank. What do you think? <I am not a

fan of drilling for sump returns, at least not too far down due

to siphoning issues.> What with live rock, crushed coral, and

live sand/gravel (from GARF) displacement eating up probably 20

gallons of space I figured targeting 2000-2100 gph for flow would

probably be acceptable. Shouldn't be able to get around there

with my two pumps returning through 1 inch PVC pipe and 1 inch

bulkheads. <Yes.> I really don't know what would be

optimum location for return bulkheads, ie. where on side walls.

Middle of front to back? How far from top edge. How did I prevent

back siphoning if pump power is loss. <Yes, this is the

problem. Some rely on check valves, but these are not to be

trusted to work 100% of the time.> I also have two Pan World

pumps with 1 inch inputs and outputs that I could use for running

circulation loop(s) or possibly throttling down one for use with

a AquaC EV series skimmer if the TurboFlotor does not work out.

<A closed loop is the way to go here. You will be able to put

the intake/return(s) where you would like to optimize flow

(perhaps even use the predrilled holes for the intake). This will

also allow you to run whatever flow through your sump you desire

rather than running the tanks full circulation through.> I

also have a 1/4 HP chiller, lots of Maxi-Jets (900'sand

1200's) and two Wave Masters. Think I need to sale some

circulation heads and wavemasters. <It always seems like you

can never have too many extra utility pumps!> Is there any

reason I should even consider putting return bulkhead holes in

the tank backwall? <Over the top will be fine. If you want to

drill consider putting it fairly close to the top (again, at

least one hole diameter from any edge) and use some Loc-Line for

adjustability to minimize siphoning.> Opinions and suggestions

please, before I start drilling, that is if the diamond hole saws

show up. Sorry this is so long, but I only have three weeks

before school starts up again and I am really antsy to get

started on this tank when I am not working. <Nice project to

work on with time off.> Its been over six years since I last

had a reef tank and things seem to keep getting better as time

goes on. My last tank was a 125 gallon with a "high"

turnover rate of 4 times per hour, 2 Maxi Jet 900's, a 20

gallon sump, 3 250-Watt 650 K halide shop lights, and a

Kalkwasser drip. No skimmer, auto top off, CO2 calc reactor, hood

with double ended halide bulbs, Actinic Power Compacts, LED

moonlights. Things do change!!! <Wow! They sure do.>

Thanks, David E. Harris <Welcome, have fun with your project,

Scott V.>

|

Manifold Closed Loop Question,

Circulation, des. 12/12/07 Hi All. <Hi

Dan> Great site with much good info. The praise never

stops! <Thank you.> I have a standard 90g reef tank

manufactured by Perfecto. It has a corner overflow with 2

bulkheads at a diameter of 1.25 inch. <Mmm, I'm

guessing outside diameter here.> I have a 3 boxed

sump/fuge below. First is sump with skimmer (EuroReef

RS135), second is return, third is fuge. I have the pvc

outlet tube T-d with some of the water diverting to the

fuge at a slow rate. The return pump is a Mag 9.5 directly

in the return part of the sump. <OK, 950gph at the

head.> I seriously need to get more flow, as I have a

huge Cyano problem that never goes away. <Yes, that 950

is probably around 800gph in your tank.> I have scoured

the site about CL systems. Since the tank is

"live", I can't drill any new bulkheads. I

don't want any 'U' tubes going over the tank

top for fear of leakage. I am thinking that my best option

is to get a submersible pump and put it directly in the

tank, maybe behind some of the live rocks to conceal it. I

am not sure what size PVC I should use for my manifold, nor

how many T-s to have for direction of output water, nor

what size diameter the T-s should be. I was thinking of

just getting some PVC and T-s from Home Depot and making

something up. I would like the T-s to be directional. I

also don't know what kind or size pump I should get.

<With two one inch ID drains you should have the

capacity to go with a larger return pump, somewhere around

1200gph. This would give you the flow rate you require. You

may consider getting a SCWD (Switching Current Water

Director) you can mount to your return line which will give

you an alternating current effect. Another way to go is to

add a couple of powerheads in your tank. A good match would

be two Aquarium Systems 1200 powerheads with a Hydor FLO

Rotating Deflector mounted to each. With shipping, you

would only have about 65.00 invested. Drs Foster/Smith has

the best prices on both items. I use this system and it

works quite well.> Much thanks, <You're welcome.