|

FAQs about

Overflows, Bulkheads/Through-puts,

Stand-Pipes, Holes vs. Boxes... Sizing, Number,

Placement 6

Related Articles: Overflow Box Arrangements,

Plumbing Marine

Systems by Bob Fenner, Myth of the One Inch Beast

(Why Relying on One Inch Overflows... or Overflow! Is

foolhardy) by Scott Vallembois, The Flow rates through various Bulkheads

(In relation to overflow drains) by Scott

Vallembois, Plumbing Return

Manifolds, Refugiums,

Related FAQs: Through Puts Placement/Number/Size 1,

Through-Puts 2, Through-Put

Sizing/Number/Placement 3, Through-Put Sizing/Number/Placement 4,

Through-Put Sizing/Number/Placement

5, & Overflows 1,

Overflows 2, Overflows 3, Overflows 4, & FAQs on: Rationale/Use,

Through-Hull Fittings, Hang-On Selection, Plumbing, Troubleshooting/Repair...

Marine Plumbing 1,

Marine Plumbing 2, Marine Plumbing 3, Marine Plumbing 4, Marine Plumbing 5, Marine Plumbing 6, Plumbing 7, Plumbing

8, Plumbing 9, Plumbing 10, Plumbing 11, Plumbing 12, Plumbing 13, Plumbing 14, Plumbing 15, Plumbing 16, Plumbing 17, Plumbing 18, Holes & Drilling, Durso Standpipes, Make Up Water

Systems, Pumps, Plumbing, Circulation, Sumps, Refugiums, Marine

Circulation 2, Gear

Selection for Circulation, Pump Problems, Fish-Only Marine

Set-ups, Fish-Only Marine Systems 2, FOWLR/Fish and Invertebrate Systems,

Reef Systems, Coldwater Systems, Small Systems, Large

Systems, Water Changes,

Surge

Devices,

|

|

|

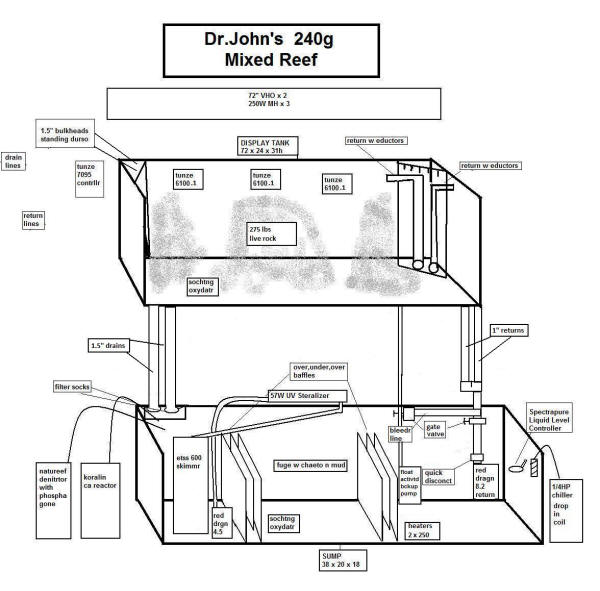

Acrylic Coast to Coast Overflow 12/19/17

Good Day,

I'm building an acrylic tank 60" x 60" x 30" out of 1" cast with top

bracing. Instead of 1 long opening on the back, I have 2 cutouts, 2-1/2" x 18"

for a semi coast to coast overflow.

<Mmm; am concerned re the structural integrity of the back now....>

They have a 6" gap between them. The top will attach in 3 places for added

strength.

<Good for the top; what about the back?>

I made the overflow box 40" x 12" x 12" . 1" thick material. Inside dimensions

are 38" x 11" x 11". I plan on having it 1/2 to 3/4 full of water when running.

My question is about the support needed for the box.

Will welding it to the tank be enough support or should I weld triangular

support gussets under it. If so will 2 work (one on each end) or will it be

better to put 3 under it?

Cheers,

Dana

<Good questions (whew!). I would add the gussets you mention. As large and as

many as you deem reasonable. Bob Fenner>

Re: Acrylic Coast to Coast Overflow 12/19/17

Bob

Here is the tank on its side. I took a picture of the back so you can see the

cutouts.

You think the back will be a problem even with the top having those 3 places as

attachment points?

<Too much stress on the remaining span... I would not have cut this tank like

this...>

Cheers

Dana

<I do hope there aren't (catastrophic) problems here. Bob Fenner>

|

cutouts on right vertical

cutouts on right vertical |

Recommendation of pipe size to use from tank to sump

3/2/17

I am setting up a new Marineland 93 gallon reef-ready tank

and have a question on what size to use on the overflow line

from the tank to the sump.

<Oh, are these units still about? >

The overflow pipe that came with the tank (from the top of the tank to

the bottom outlet bulkhead) is 1 1/2" PVC but goes into a reducer at the

bottom that takes it down to 1" to go through the bulkhead.

<Uggh! Too small to be of real use>

My sump has single inlet that is also 1" pipe. The return plumbing is

all 1" pipe.

Is there any advantage for either increased flow or quieter water

movement if I use anything bigger than 1" PVC from the overflow to the

sump?

<Oh, yes... what's the formula for an area of a circle; pi R squared?

Try some examples>

Or is it the same if I just plumb everything using 1" PVC?

<The same what? Read here:

http://www.wetwebmedia.com/SystemPIX/PlumbingPix/Oneinchart.htm

and the linked files above; re options... My long and short: DO most of

the circulation in the tank... USE the sump as a too-small refugium,

gear holder. Bob Fenner>

Thanks!

Plumbing issue 6/15/15

Hey guys question for you... I just got the new 90 up and running yesterday but

today I have a problem... I have a 90 gallon deep blue RR system

<Not the one inch plumbed MarineLand system I hope/trust>

all hard plumbed, reverse duroso in the sump and the stock duroso in the

overflow, I am running a Mag 9.5 with a manifold running my uv, carbon and gfo

reactors plus the return. I installed 2 RW-8 pumps this is my problem I think.

They are placed on opposite ends of the tank, the one near the overflow is

pointed downward and the other is pointed straight across the

tank back at the overflow, I have them running in "C" which is alternating

pumps. My problem is as they are alternating, the level in the overflow drops

and rises and so does my pump chamber which is causing my vent on my reverse

duroso to shoot out water. How can I fix this and have you ever heard of this

before?

<Yes; I'd try moving the internal pumps first.... to another corner, perhaps

just a bit lower in the tank... away from the overflow. I would put a piece of

pipe (riser) on the Dursos, and maybe a reducer to like 3/4 or 1/2" w/ a small

piece of pipe (just pushed in, no need to solvent) in this/these in turn... to

quiet down, reduce splash and spray...>

...I have already drilled bigger vent holes for 1/2 flexible pipe and it did

make it silent but no help on the surging water levels...

<And a note again re the diameter of overflows... yours may well need to be

larger, re-drilled, or at least added to here... the 9.5 will overwhelm 2 and

more 1" IDs. Bob Fenner>

Fluctuating Sump Level; one inch drain line/s

11/9/14

Dear WetWebMedia,

<Mich>

Thank you so much for your service to the aquarium trade. I have

successfully kept a reef tank for seven years. My original fish are

still alive and thriving. I owe it to following the advice I've learned

on this

website.

<Ahh>

I apologize in advance for my lack of physics knowledge. I also

apologize for the lengthy email as I don't know what information is

important. A couple months ago I moved and had my reef tank upgraded to

a 120 gallon tank at the same time. It is a room

divider tank and visible on three sides. The overflow is located on one

side of the tank. It currently has one 1" drain

<Mmm; too small... needs to be... "over-sized"... at least 1.5 inch for

this volume system, sump... in fact, two drain lines would be preferable

to one... Oh, I see below...>

with a Durso, one 1" drain that is unused,

<I would use this drain as well>

and a 3/4 inch return. The return is rated at 1200 GPH. There have been

problems from the start. The Durso appears to be tuned correctly with no

flushing. To start, the drain line vibrated/shook and sounded

like a dishwasher.

<Yes; overwhelmed... siphoning intermittently.... maddening noise wise>

We attempted to solve it by cutting the drain line shorter to allow it

to hang straight down and just below the water level in the filter sock.

The noise and shaking continued.

<Ah yes>

We then drilled a few holes in the line to allow air to escape. This

greatly reduced the shaking and noise, but did not eliminate it.

<Won't do so... either have to slow the rate of flow down (by pumping

less), OR adding another drain (of size), OR re-drilling the present

drain line, fitting a larger through-put/bulkhead fitting and larger

diameter

pipe>

I have an auto top off unit in the sump/refugium that beeps if the water

level rises above the sensor. At least once a day the water level in the

sump rises and sets off the alarm. Tonight when it happened, I watched

the sump water level go back down to below normal. I then noticed that

the water level was unusually high (by a couple inches) in the overflow.

The water level was higher, but not "flushing." It also seemed like the

drain line was substantially quieter. I turned the pump off to check for

an obstruction in the drain line, but couldn't see anything. When I

turned the pump back on, the level in the overflow was back to normal,

but the level in the sump was too high again. It makes me nervous having

the water

level fluctuate like that.

<Ah yes>

Do you have a guess as to what the problem is?

<Indeed I do... very common w/ undersized plumbing as you have here...

the system is oscillating twixt flow and siphoning down the one drain

line... when the water is backed up in the upper tank, the sump is

drained sufficiently to set off the auto top off alarm...>

I'm assuming the problems have something to do with the drain not being

able to handle the return rate. Is that correct?

<Ah yes>

If so, would it help to utilize the extra 1" drain?

<I would employ it and hope it does so>

If so, is it ok to have two dursos in the same overflow?

<Yes>

I already inquired about making the drain holes bigger, but was told the

holes were as large as they could be with there being three holes in the

same small area.

<Yes; an engineering/design defect. There have been quite a few

commercial systems... and custom with this mistake>

Thank you in advance for any help you can give me.

Michele

<I would first try using both one inch drains... IF this doesn't "do

it", I'd slow down the rate of flow to/from the tank... and provide more

flow INSIDE the main/display tank with submersible pumps (see WWM re);

using the sump less... IF this doesn't satisfy, the present holes can be

abandoned, a piece of material placed over them and the tank/drain area

re-drilled, WITH one larger drain line (2" if it were up to me) and a

one inch return. Bob Fenner>

Re: Fluctuating Sump Level

11/10/14

Thank you so much for your help! We opened the second drain line and

added another Durso. So far so good! It looks like it is now draining

properly. And the tank is so much quieter!

Thanks again, Michele

<Ahh; good news. Thank you for your report. Bob Fenner>

Water Flow/Volume... <<RMF addenda>>

5/13/13

Your site is awesome, not enough hours in the day to sit and read all

the information that is available. I also think my wife is starting to

feel a little neglected. oops. As for my questions, I have a

6' long 125 gallon aquarium with an additional 75 gallons in a sump and

a refugium. My goal is a reef system with limited fish,

mostly inverts and corals. I am particularly drawn to LPS coral and some

polyps. The display tank is on main floor, and

equip is in a dedicated basement room. If "dilution is

the solution" for reducing pollution would my tank benefit from adding a

175 gallon poly tank in my basement. I have plenty of room. I

currently have a Mag 36 pumping water from sump to DT, gravity

would provide flow from DT to poly tank then sump with skimmer, then

refugium and then to pump chamber in sump. I would raise the poly tank

off the floor so I could drain some water from bottom to remove any

settled detritus from the tank. The pump is reduced to 2200 gph because

of head pressure, and reduced more due to plumbing size restrictions.

I'm not sure final actual water circulation. I don't have any

other pumps or power heads running, I was relying on the Mag drive.

My tank is drilled and has overflows in the 2 back corners and 2

additional bulkheads installed near the top also on back wall. I

believe all 4 bulkheads use 3/4 pipe fittings which are too small I know

but its what I have. This creates a lot of water noise due to

volume moving thought small piping.

<<Yes; I'd abandon or drill out these fittings, through-puts... replace

w/ 1.5", or 2" ID>>

I am wondering if I would be better served by replacing the Mag 36 with

something smaller like around 750-1000 gph after head pressure

adjustment, returning this water to DT thought the 2 bulkheads in the

middle of the back wall, then add another circulation pump attached to a

closed loop system with 4 or 6 outlets.

<<Yes; much better served. Along w/ the (still) redrilling of the

overflows (and as large a fitting diameter as the discharge on the

volute of the pump you settle on for the sump/main tank return). I would

definitely do this>>

Water only escapes the DT from the top of the water column in the overflow

boxes, should I be removing water from near the bottom of the tank also?

<<Mmm, not likely of use, much benefit, IF you're adding sufficient

'in-tank' circulation... this latter will "stir up" the bottom water

enough...>>

If so how is this safely accomplished.

<<.. Can be done in a few ways... a "tee'd" (aspirated to the air at the

top to break/disallow siphoning) line that has an extension to the

bottom area is likely best for this sort of hobbyist setting). Again, I

wouldn't do this>>

I plan on using a DSB soon.

<<Good>>

Also I use 3 -175 watt MH lights, do you feel this is enough for LPS like,

frog spawn, hammer coral, bubble coral and so on... I have been

considering switching to 250 watt MH... thoughts?

<<Mmm... I wouldn't likely switch from the 175s... better to just raise

the LPS, other "light intensity loving" corals to higher levels on

rock... use a PAR or PUR meter to ascertain light energy.>>

or maybe consider LED

<<Ah yes; if you can afford the initial investment... look to units that

can be modified, adapted to another (likely larger) system>>

instead. I'm thinking I need to do something different with lighting

because my frogspawn is not opening big for a while now and also my

zoo's haven't been opening either.

<<See WWM re allelopathy... the better chance of what's going on here.

Bob Fenner>>

I tested and have 0 ammonia, 0 nitrites, 10 nitrates, (down from 20

forever.. finally progress) 8.3 pH, 425 calcium, don't have alkalinity

or phosphate test. Thinking its water flow or lighting. I sincerely

appreciate what the staff at WWM does, living in western Iowa there

isn't much for LFS here. Plus never get same answer twice. Thanks

again for giving of your time and opinions.

Thanks

Shawn

<Hi Shawn,

I'm Darrel - I usually answer reptile questions and although I have a

Marine tank, I usually leave the aquaculture questions to the real Pros

like Bob, James, Neale, etc. When I do chime in, it's on the

engineering level at which I am very well qualified.

The reason your letter caught my eye is because I, too, like doing

things in a large scale and rely heavily on the engineering aspect to

solve the technical problems -- so for that reason only, I want to chime

in on one, tiny concern I have ... just food for your consideration --

AND NOTHING MORE -- then leave the real answers to the real pros.

Yes, Dilution is a great solution or at least a really great

asset in our systems. With enough back-tank storage, you can

make a 125 gallon tank carry the bio-load of a 350 or 400 -- we just

think of it as a 400 gallon tank with all the fish residing in the same

125 gallon portion of that much larger amount of water.

It's a cool and elegant solution.

Until the power or the pump fails -- and suddenly the 350 gallons of

bio-mass are now stranded in the 125 gallon portion of the tank where

the toxicity now increases exponentially. Since the bacteria of

the nitrogen cycle grow on virtually ever wet surface in your system --

and they grow to the limit of their food source. What I'm saying

is that in the proposal you mention below (125 gal tank and then 75 + an

additional 175 in the basement) maybe as much as 2/3 of your nitrifying

bacteria are now cut off from the system in which the bio-mass resides.

My concern would be that completely separate circulation systems are

absolutely necessary in a situation like that and in reality there

should be a third, totally separate circulation system that uses a low

volume, low power pump that is fed from a backup UPS system like we use

in home computer systems. >

Water Flow/Volume – 05/13/13 /EricR

Your site is awesome,

<<Thanks…a collaborative effort>>

not enough hours in the day to sit and read all the information that is

available.

<<Indeed>>

I also think my wife is starting to feel a little neglected. Oops.

<<Uh-oh>>

As for my questions, I have a 6' long 125 gallon aquarium with an

additional 75 gallons in a sump and a refugium. My goal is a reef system

with limited fish, mostly inverts and corals. I am particularly drawn to

LPS coral and some polyps. The display tank is on main floor, and

equip is in a dedicated basement room. If "dilution is the solution" for

reducing pollution would my tank benefit from adding a 175 gallon poly

tank in my basement?

<<It would…as long as you don’t overstock the display beyond what can

“get by” for a couple hours in the event of a power outage>>

I have plenty of room.

<<Go for it!>>

I currently have a Mag 36 pumping water from sump to DT,

<<A big pump…>>

gravity would provide flow from DT to poly tank then sump with skimmer,

then refugium and then to pump chamber in sump.

<<Ok>>

I would raise the poly tank off the floor so I could drain some water

from bottom to remove any settled detritus from the tank.

<<Good idea>>

The pump is reduced to 2200 gph because of head pressure, and reduced

more due to plumbing size restrictions. I'm not sure final actual

water circulation.

<<Easy enough to test if you can direct the output on to a container of

known volume and “measure” how long it takes to fill>>

I don't have any other pumps or power heads running, I was relying on

the Mag drive.

<<I personally prefer to not run large volumes of water through my

sump/refugium/et al, and use “propeller” pumps (e.g. – Tunze Stream

Pumps) to create flow within the display. Not only are the

propeller pumps much more efficient re…reducing transient flow through

the display/sump greatly reduces or eliminates issues with noise,

bubbles, etc.>>

My tank is drilled and has overflows in the 2 back corners and 2

additional bulkheads installed near the top also on back wall. I believe

all 4 bulkheads use 3/4 pipe fittings which are too small I know but

it’s what I have. This creates a lot of water noise due to volume moving

thought small piping.

<<I have no doubt>>

I am wondering if I would be better served by replacing the Mag 36 with

something smaller like around 750-1000 gph after head pressure

adjustment,

<<I think you could even get by even with 500 gph after head-loss>>

returning this water to DT thought the 2 bulkheads in the middle of the

back wall, then add another circulation pump attached to a closed loop

system with 4 or 6 outlets.

<<You could do the closed-loop…but you will use a lot less power with

MUCH better flow by dispensing with the CL and going with a couple

propeller pumps>>

Water only escapes the DT from the top of the water column in the

overflow boxes,

<<As it should…to help keep the organic film that develops at the

air-water interface cleared away>>

should I be removing water from near the bottom of the tank also?

<<Not in my opinion…you don’t want to drain the display dry in the event

of a power interruption. In fact, your overflows at the surface should

be set so that your sump can easily handle/hold the transient water

volume in such an event>>

If so, how is this safely accomplished?

<<It isn’t>>

I plan on using a DSB soon. Also I use 3 -175 watt MH lights, do you

feel this is enough for LPS like, frog spawn, hammer coral, bubble coral

and so on...

<<yes>>

I have been considering switching to 250 watt MH... thoughts?

<<Not necessary here>>

or maybe consider LED instead.

<<Is an option>>

I'm thinking I need to do something different with lighting because my

frogspawn is not opening big for a while now and also my zoo's haven't

been opening either. I tested and have 0 ammonia, 0 nitrites, 10

nitrates, (down from 20 forever… finally progress) 8.3 pH, 425 calcium,

don't have alkalinity or phosphate test.

<<Do get a test kit and check this…low Alkalinity may well be the issue

with your corals>>

Thinking it’s water flow or lighting. I sincerely appreciate what the

staff at WWM does; living in Western Iowa there isn't much for LFS here.

<<We’re happy to assist>>

Plus never get same answer twice. Thanks again for giving of your

time and opinions.

Thanks,

Shawn

<<Happy to share… EricR>>

Re: Addended: Water Flow/Volume 5/13/13

Thanks Bob

In your opinion then would I be better served using a pump and closed

loop with multiple openings or just use a couple propeller pumps in the

DT.

<The latter by far... See WWM re... closed loops are passé for several

fundamental reasons.>

In 125 g tank what volume of water should I be looking at moving.

<Also gone over and over... Do you need help using the indices, search

tool? B>

Shawn

Overflows, Sumps and Pumps (Oh My!) – 08/16/12

Hello Wet Web,

<<Greetings Brenda>>

I've read a lot of your info since March of 2011.

<<Excellent…do keep reading!>>

You have helped me a lot and that is an understatement!

<<Ah! Is redeeming to know>>

I have a 55 gallon tall tank, 30’’ long, 24’’ high, and 18'' wide.

<<Ah yes…the ubiquitous 55>>

The glass is tempered, so no drilling.

<<Okay>>

I'm thinking of putting an overflow on the tank. The tank has some

corals, a few sps, lps and Zoas and mushrooms, plus a couple of fish. I

want to get a CPR overflow, but don't know which one. I would like to

get the one with 2-1.5’’ holes, I think it is a 1500gph, but am afraid

it might be too big for a 55 gallon.

<<Is more than you “need” in my opinion. Going with a smaller setup

(2-1” or 1-1.5”), and even then sizing/regulating your return pump to

provide flow equal to half the return’s capacity for redundancy/safety,

will be enough circulation yet a whole lot less headache re

noise/bubbles/plumbing issues et al>>

I also need to know what size sump

<<As big as you can fit…for many of the reasons just listed. But for

sure nothing “less” than 15 gallons>>

and what size pump?

<<For the size overflow I have recommended, something that will give

about 300gph with whatever head-loss your system will provide>>

As you can see I'm a little afraid of an overflow onto the floor with

all the water and I don't have the extra money for costly mistakes I'm

going to make.

<<Understood…but many benefits to be gained by adding a sump. Though

there are those (some here) who would say they would do without rather

than rely on a siphon-style overflow>>

Believe you me, I have made a few even with all the info I've read here

and other places!

<<Mmm, me too…even after many years in the hobby>>

Also if I don't go for the overflow which I really want, how many power

heads should I put in there and where is the best places to put them.

<<Enough sized to provide flow at some 500+ gph…and positioned near the

top to provide a “GYRE” type flow pattern>>

So what do you say guys, can you help a lady out?

<<Hope I have… Do research WWM re the terms I have used (gyre, head

loss, etc.), along with sump plumbing and design, and then come back

with more questions if you wish>>

Thank you.

<<Happy to share>>

I know you gentlemen

<<Ladies here too!>>

are very busy.

<<We’re here to help…>>

Brenda

<<EricR>>

|

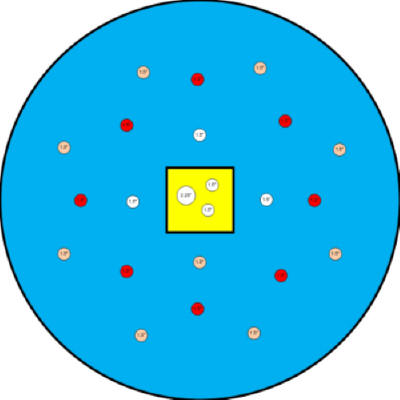

Re still having trouble with layout and believe me I have

read...and read..... SW overflow pb... 6/25/12

Appreciate all you do. I am setting up a new tank, 60" x 18" x

26",

visible from 3 sides. I want to use a Beanimal <check your spelling

here>

version of the coast to coast overflow. At the same time, I

would like to install a closed loop manifold.

<... these are really not the more/most useful, best available

arrangements nowayears... Better by far to use internal pumps

for most circulation, a minimum of overflow tech. to convey water out/in

of systems...>

A. The problem I am having is, Where

and how many holes do I need to drill into the back of the tank.

The "where" is an issue for me because of the coast to coast design.

If I make the overflow a true C2C, then the return from the sump would

empty into the "trough". Don't think that's acceptable ;)

<... Please read here:

http://www.wetwebmedia.com/thrhullsiz6f.htm

and the linked files above>

Available options I see are:

(1) Delete the drilled sump return and come over the top, not really

what I want to do. {the red line is the C2C}

<I would definitely NOT do this>

(2) Drill an additional hole for the same size bulkhead in the front

panel of the C2C directly perpendicular to the Sump Return in the back

wall and span the C2C with a short section of PVC to the second Bulkhead

[see attachment ] and into the tank. This same process would have to be

repeated for the CLM Plumbing and I would have to figure out a way to

attach the Manifold PVC to the top front of the C2C Front Panel,

since I could not zip tie it to the tank frame here. I would also be

forced to cut across the sump return with the manifold plumbing [see

attachment from above]

<A possibility... >

(3) Make the Coast to Coast an Almost C2C by cutting its length short of

the Sump Return. not my favorite idea. Clears the return, but doesn't

alleviate EITHER the manifold still needing to be attached to the front

glass panel of the C2C OR the manifold requiring the plumbing to come

through the C2C.

My question is, am I missing something, a better way perhaps?

<Read where you've been referred... there are other possibilities>

B. As for my dilemma with the number of

drilled holes in the back glass, based on my research I need 7. [See

attached drawing] Will this endanger the structural integrity of

the tank?

<More holes, more poss. problems... I'd keep these to a minimum... like

two>

I would really appreciate any guidance you guys can give me.

Thanks,

Darrell

<Just my opinions, personal et al. experiences. BobF>

|

|

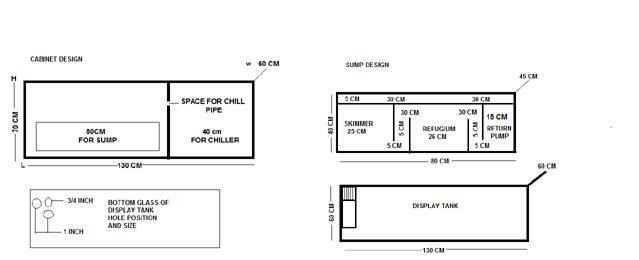

New custom build - 05/11/2012

|

|

Hi crew! Hoping to trouble you again with my questions, this time about a new

build I am planning. I am looking at a 130 by 70 by 60 cm tank with orphek LEDs,

a reef octopus extreme 200 skimmer, 2 vortech mp40s and a 3 pump doser. I have

sketched out a design and was hoping to get your thoughts on it. In particular,

I am unhappy with the sump and fuge but not entirely certain how to improve

these. I am already looking at increasing the size of the sump by removing the

space allocated to the chiller.

|

|

wwm: Good

|

|

Doubt I will need the chiller given the temperature of the room. I was also

looking at changing to a central overflow with a split return to improve flow.

|

|

wwm: The

position you show here (in the back corner) is fine... I'd likely settle on one

overflow line of 1.5" ID, rather than the two one inch ones shown... pi r

squared will show you that the single larger will accommodate much more flow,

and there's less likelihood of crack issues

|

|

I would appreciate any other suggestions you have as well. Cheers, Paul

|

|

wwm: Do scan

here:

http://www.wetwebmedia.com/marsetupindex2.htm Bob Fenner

|

|

|

Re: New custom build

– 05/13/12

<Ahh, please do>

Thank you. I will revise and run it by you if you don't mind. Have a few new

ideas.

Cheers,

P

<And you, BobF>

|

|

HOLES 4/13/12

BOB ,

The tank builder has drilled a hole through the base of DT the

glass of which has then been toughened and tempered.

<Really?>

Its in an inside weir compartment so can only drain that

overflow/weir.

Knowing your professed antipathy to holes in base I ask you - should I

be concerned?

Robert

<Not really. B>

Cube 1100x11000x600

Refugium Upstairs 2000x750

75 gallon help, hole drilled too

low 4/5/12

Hello Wet Web Media Crew. I recently purchased a 75 gallon and

proceeded to drill the back of it with 1 1/2" hole. I am using a

DIY 20 gallon long sump and a 700 gph overflow box. However, my

aquarium problem is that I drilled my overflow hole too low and do not

have enough room in my sump to hold the excess water when the return

pump is disengaged. I have created a flood situation. So do you think

that I could drill another hole on the other side of the tank that is

higher up for the overflow and use that 1 1/2" hole for the

return?

<Can/could be done. Do elbow up the discharge... such that it is

near/above the water level... lest it too serve as a source of water

below when the power or pump goes out (Do NOT rely on check

valving)>

If going that route how would I ensure that the return line be

positioned higher within the tank so that it would not siphon out 10

extra gallons into the "too small" sump?

<See above>

I understand that some tanks have low return lines, but how do

they keep their tanks from completely draining when the return pump

gets turned off?

<Discharges higher than water level...>

I was also wondering if I was to drill two return holes, and put

the overflow in the middle, would that help if I thought my pump in the

sump was too strong and was returning the water faster than what the

overflow was draining?

<Mmm, no... Read here: http://www.wetwebmedia.com/thrhullsiz6f.htm

and the linked files above till you understand, feel confident in your

plans. Bob Fenner>

Thank for the help!

Tank Volume Pump Output Overflow

Capacity 1/20/12

Begin forwarded message:

> Crew. Hello.

<R>

> With two 2" overflows according to your <ScottV's>

tests able to drain 1350 gph with a tank volume of 190 would you aim

for a calculated return pump output of a little less than 1350gph or

5000 litres to ensure that a single 2" overflow would cope if the

other failed? <Yes> This would give a x7 or less tank volume

through the sump per hour assuming that in rank pumps would be employed

to push circulation volume is this kind of thinking about flow on track

?

<About>

> Regards>

> Robert

<B>

drilling/plumbing new 180 g acrylic

12/17/11

Hello, crew. I recently acquired an un-drilled 180 g acrylic (6x2x2)

and am new to this wonderful hobby. My years of scuba diving finally

led me to start my first reef setup.

<Ahh! A good source of momentum, instruction>

The tank has been sitting in my garage as I have been doing research on

gear and getting everything I need. I have a Berlin-style sump being

built (30x13x14), which will use a BlueLine 40 HDX Pump

(http://www.aquacave.com/blueline-40-hd-x-externalbr-aquarium-water-pump-brby-pan-world-534.html).

I also had a refugium built that would just fit in the cabinet space

next to the sump. My skimmer (still in box) is a Reef Dynamics (i.e.

Euro-Reef) 180

(http://www.reefdynamics.com/INS180-Protein-Skimmer-p/ins180.htm ),

which will be in-sump. I am having a local LFS guy do the drilling in

plumbing as soon as the gear is all in order.

<Ok>

The Sump/Refugium manufacturer has finished early and is asking me what

size plumbing I will have done on the tank so they can have the correct

sump inputs and return manifold. The manufacturer (LifeReef) is

recommending only 1" to 1 1/4" drain holes

<Mmm, a mistake... these (more than one) need to be larger. Read

here re:

http://www.wetwebmedia.com/SystemPIX/PlumbingPix/Oneinchart.htm

and as much of the linked files above as it takes to inform you>

and .75" return

<Mmm... whatever the diameter of the discharge of the pump (on the

volute) is>

holes (4 total), and my local guy (who will do the drilling/plumbing)

is on vacation right now and will be unreachable for 2 more weeks.

Although I have done a good deal of research on various aspects of

keeping a reef tank, I have been extremely busy and done little in the

way of drain hole recommendations and subsequent flow rates. From what

I have read, it seems many here feel that bigger is better (like

2" drain holes). I have done some research on circulation and plan

to get the appropriate water movement for this coral setup (plan on a

few SPS in the mix) through several Tunze powerheads.

<Good>

My question is should I follow the sump manufacturers advice for the

two 1" drain holes or go bigger?

<Bigger>

I know the fact that I don't even know exactly what overflow system

I will use yet probably doesn't help any. I can have the holes

drilled to whatever size is recommended, but the sump manufacturer

needs this info before my knowledgeable local guy is back. I inquired

today at the LFS but the staff there that day couldn't offer much

as their main guy is on vacation, as well.

Sorry for the newbie question, I just didn't expect to have to know

this until I was able to do more research. If you need any more

information I will gladly provide it.

Thank you so much,

Kevin

<Do first read where you've been referred to above. Take your

time. Cheers, Bob Fenner>

Re: drilling/plumbing new 180 g acrylic 12/17/11

thank you so much. I am calling him now to have the 1.5" drain

holes.

<Ah, good. BobF>

Regards,

Kevin

Re: drilling/plumbing new 180 g acrylic, overflow f'

12/18/11

Hi WWM crew. So sorry to bug you again. I just need to make sure I am

doing the right thing here and am getting contradicting information

from my sump manufacturer. This is the response I received when I

replied that the drain holes drilled into my new acrylic tank would be

1 1/2". Initially, it was my mistake as he recommended 1"

drain holes and I didn't know enough to tell him any differently.

Then, I read your article and called him asap. Please give me your two

cents so I know what to tell him.... (his response below)

"I've already glued in the two 1" inputs to the sump,

which is ok for this sump and pump setup and pretty standard for many

manufactured aquariums.

We'll never come close to what two 1 1/2" fittings would flow

and it would be too fast, noisy, turbulence, etc for this sump and we

certainly don't need the faster flow rate through the sump.

<What? No... idiocy. Refer this person to the relevant parts of

WWM>

You are putting in some powerheads or wavemaker pumps in the

aquarium?

This is what most do to get the needed in-tank water circulation and

currents.

See if your tank guy can get two 1 1/2 x 1 reducer bushings to go into

the bulkheads and then 1" tubing can be plumbed to the sump.

What size are the two return lines?"

<... See where you've been referred to>

...should I insist on the 1.5", and, if so, would I still use

3/4" return lines? Is what he is suggesting regarding the reducer

bushings in the bulkheads fine, or should I insist on different inputs

on sump.

Please help as I am pretty new to the hobby, not wanting to make a

mistake, and paid a good deal for this sump/refugium combo. Thank you

so very much.

Kevin

<Please... Search, read before writing us. B>

Drain Question, overflows, SW, RR...

11/20/11

Hi WWM posse!!

<Yee hay!>

I have a question on drainage/return on my 180g RR tank.

<Ugh... NRR... Not Reef Ready more like it>

The tank has dual

overflows on the back panel, I have a Eheim 1262 with flex hosing going

to a 1" PVC return in each overflow.

<Oh, this can work>

I was hoping that I could have just one single Durso drain in the left

overflow and make an emergency drain for the right overflow.

<An emergency overflow... for what? An ATOff system error? I'd

use both for overflows to your sump>

Do you think that this will be okay or should I have a drain in each

overflow?

<The latter. Am a much bigger fan of downsizing the flow to and

through the outside, and using internal pumps for circulation. Do

scroll down here:

http://wetwebmedia.com/marsetupindex2.htm

the third tray>

Thanks in advance, you guys rock!!

Brent

<And roll! BobF>

Plumbing/Draining Question. Bulkhead

size... 7/14/11

Hi WWM!

<Hello Mike>

Thanks for having such a great resource to use with an awesome bank of

knowledge.

<You're welcome.>

You helped me with a lot and I just had a question that elaborates

further on what someone had asked already. Here it goes....

First is what my setup is now. I have a 60 gallon

acrylic tank without any internal overflow boxes or

holes drilled yet. My plan is to plumb it to a 20

gallon sump I have down below which will have a filter sock,

protein skimmer and one internal return pump to one 1" return back

to the tank. I am only planning to do one return but don't mind

later when I get a stronger pump. I also have a 10 gallon refugium

which is on a stand higher than the sump to gravity feed it. My

question has to do with what the best option for my outlet(s) to the

sump would be. I was going to go the siphon overflow route until I

started reading all the troubles with that type of setup on the net so

now I want to drill my tank. That had a 1 1/4" bulkhead, Is that

appropriate for my tank?

<Is this for 1 1/4" hose or just the size of the bulkhead

mounting diameter? Generally, 1 1/4" bulkheads are for 1"

slip or NPT and this would only give you 350gph at most provided there

are no restrictions such as elbows, etc.>

I also read here I should have two in case one gets clogged. Should I

put one on each side?

<I would.>

The second part of this is that I had an idea to cut the back of my

internal side of the siphon overflow's back off (also acrylic) and

leaving about a 1/2" or so rim around it. Then I would glue it to

the inside of the back of my tanks with acrylic glue. Do you think this

would work?

<That sounds like a nightmare, go the bulkhead route, you will be

glad you did.>

However this only has room for one bulkhead inside. I read somewhere

that people use elbows but I'm worried they won't skim enough

of the surface.

<Not good.>

If you do think that this is a good idea would it be better to do the

drains in two separate smaller boxes (such as 6 x 4 x 4) or would it be

better for a long one (such as 15 x 4 x 4) in order to house both of

the bulkheads. I will contact www.wetdryfilter.com with specs of your

recommendation if you think this is a good idea or not.

<Best to have two corner overflows with bulkheads. If you go with

one, use a bulkhead fitting that will accept a 1 1/2" drain hose

or PVC pipe.

Might want to look here for flow rates on bulkhead fittings.

http://www.wetwebmedia.com/BulkheadFloRateArt.htm

Also read here and related articles/FAQs found in the header.

http://www.wetwebmedia.com/plumbingmarart.htm>

Thanks!!!!

<You're welcome. James (Salty Dog)>

Mike

Re Plumbing/Draining Question 7/14/11/7/15/11

Thanks for such a fast reply!

<You're welcome.>

1 1/4" is the size of the bulkhead which goes to one hose. After

seeing your response, two seems like the way to go for drains.

<Is better for larger tanks. A 1 1/4" bulkhead accepts a

1" PVC if a slip bulkhead, so we are back to a 1" drain

hose.>

Do you think these are big enough?

<Yes, two 1" drain lines should give you a minimum of 600gph

flow into the sump.>

What size would you recommend? I would eventually like to get a

stronger pump than I have.

<Depends on the pump you want to upgrade to. Generally a flow rate

of 10-15X the tank size is recommended if this is going to be the sole

source of water movement.>

I think I may have not been very clear about the overflow box idea. I

wanted to cut away the back and glue it to the inside of the tank in

order to use it as an overflow box with a bulkhead.

<Mmm, one of our crew members produces complete kits to do what you

state.

The kits are very reasonable and work quite well. Might want to take a

look here, I think this is what you have in mind. http://www.reefercentral.com/whyglassholes.html>

I do not want to siphon at all from all that I have heard. This would

be just to save money since the tank I bought came with a siphon

overflow but I do not want to use it.

<Yes, seems like you are always fiddling with them.>

I am essentially trying to do a "through-the-back" overflow

that your article in the first link speaks of. That leads to this

following question... Is it ok to have two drain holes in one long box

or should they each have a separate box?

<Will all depend on what the weirs are capable of flowing.>

Also what do you think an appropriate drain setup would be? I was

thinking I would do two bulkheads that feed to 1 1/2" drain tube

evenly spaced apart in one 15"x5"x5" through the tank

overflow box.

<I would prefer individual drains to the sump. Should you want to

clean one or do maintenance, you would always have the other drain to

feed the sump.>

Is it inherently more noisy if the return pump is only pumping with

300GPH to start with?

<How could it be noisy, explain.>

Also you had mentioned using corner overflows. Do you mean the full

length ones drilled at the bottom?

<Yes, but the overflows I linked you to will work just as

well.>

Do you think they are better than smaller boxes at the top?

<Obviously the boxes give more room for aquascaping and if I were to

order an acrylic tank I would not want it built with internal boxes,

would go with the Glass Holes design. The choice is

yours to make.>

That should be it for the questions I swear. =)

PS Thanks for the links. A lot of additional great info there I

didn't see.

<You're welcome.>

The last question I forgot was how far down from the top of the tank

you should drill for the bulkheads when using a small overflow box at

the top?

<I'd want 1" between the top of the tank and the top edge

of the hole.>

THAT is the last question for sure. Promise.

<Promises are meant to be broken. :-))>

Thanks again,

<Yer welcome. James (Salty Dog)>

Mike

Re Plumbing/Draining Question 7/14/11 7/15/11

7/16/11

Thank you tremendously! EXACTLY the link I've been trying to find

on the internet to see if anyone has done or I was going to try and

make it, but they even sell them!

Thanks again,

<You're welcome Mike. James (Salty Dog)>

Mike

Water Flow/Water tower

2/23/11

Hello Crew, fantastic site, thanks for the wealth of information.

<Thank you.>

Here's what I'd like to do if it's at all possible, I want

to create a water tower that is filled by draining water into it from

the bottom. The tower fills and then overflows.

<Okay.>

Here's the scenario: I have a 500 gallon tank (8'x2x4), it sits

on a 3 foot stand. Because of a space issue, I'm building a

filtration rack that stands 6 feet tall and has four levels. Without

using a pump, I'd like to get the water in the water tower to rise

to the top and spill over into the top of the filtration rack and of

course at that point, flow back down to sump level (ground level) where

the return pump is located.

My idea of how I can get the water to fill the water tower is to have

the water from the tank flow into the bottom of the water tower (made

out of 2 3' foot plastic barrels ). The water tower will have a

2" bulkhead located 6" from the bottom. The two 1 1/4"

overflow lines will be tee'd, the out portion of the tee will be

2". The barrel will sit 2 feet off the floor, so it's opening

will be appx. 1 foot lower than the bottom of the tank.

(Finally, here's the question) Will the barrel fill to the top

(where there is a spout (if you will) that will allow the water to flow

directly into the top of the filtration rack.

Or, am I dreaming

<So long as the level in the barrel is lower than the tank the water

is draining out if it will be fine. For what it is worth I would

definitely go larger for the tank drains if you can. 1.25" lines

will give you about 500 gph each at best. Also, route the overflow from

the tank to the containers as direct as possible. Many bends and elbows

will take away from the line's flow capacity quite quickly.>

Can't wait to read your response, thanks Lee

<Welcome, Scott V.>

Making a peninsula out of a RR tank,

overflows, plumbing mostly 2/22/11

Hey guys I am looking for an opinion and of course some good advice

which you always offer. I currently have a 150 RR tank established for

7 years or so. We moved and now the way our house is we decided we

would like to have a peninsula tank to divide a couple rooms.

<Okay.>

So I came across a very nice 265g perfecto with corner overflows. I

would have rather had a non drilled tank but the opportunity came along

and I jumped on it. Just want to know how you feel about converting

these types of tanks into a 3 peninsula style display?

<Fine, but the overflows are likely the lacking 1"

variety.>

I initially intended to:

1. Remove overflows, use bulkheads and cap them. Then drill one end and

make an external overflow maybe implementing a Herbie style

overflow.

2. Remove overflows and use the holes for a closed loop. Use street

elbows and run a pipe to the center, hide it under sand and rock and

have a couple closed loop returns in there. And drill the one end like

previously stated.

3. Remove only one overflow, cap the bulkheads and use the remaining

overflow and not drill the tank at all. This seems easiest and if I

ever decide to revert the tank back to its original glory, it will not

be too hard. Only problem is I imagine that one corner overflow will be

a little unsightly.

Ahh decisions decisions. What would you do if it was yours?

<Not option 3. You will need to drill no matter what you do IMO. One

1" overflow just is not enough. And I would skip the Herbie idea

all together. They sound nice in the forums, but are a recipe for

disaster.

Drill and drill for redundancy. See:

http://www.wetwebmedia.com/BulkheadFloRateArt.htm

If you intend to run a closed loop I would use the existing holes for

this.>

Thank you, keep up the great work!

<Welcome, Scott V.>

Re: Making a peninsula out of a RR tank 2/22/11

Scott thank you for your advice.

<My pleasure!>

One more thing about the option 3 that I forgot to put in the

description, sorry. I would be using both 1" holes as overflows

and then run my return from the sump up over the non visible side of

the tank. Indeed they are the lacking 1" but do you think 2 would

be sufficient?

<They could be. Here is my deal. The real world practical limit for

a 1" is 300 gph. Have two, flow what one will flow for true

redundancy should one plug up for 1000 reasons. Even then I like larger

overflows, they are much less likely to plug. In many hours of actually

testing overflows I have thrown the dumbest stuff into the tank to see

what happened.

Something simple like a paper towel that makes its way in easily plugs

a 1" 95% of the time, where it will flow straight through a

1.5" 99% of the time. Larger bulkheads not only provide more flow,

but more security that the water will stay where it should!>

If not I will be drilling for 3x1.5" overflows

<This is exactly what I would do. It also keeps the visible corner

looking good!>

Thanks again

<Welcome, have fun!>

1 inch over flow bulk heads.

2/11/11

Hello

<Hey there.>

I have a question for you. I am one of the lucky ones that have 1 inch

bulk heads the found you site and discovered there actual flow

rates.

<You are not alone, the whole reason the testing was done!>

Is there any way to increase there flow rate?

<Sort of. I have been working (for 3 years now) on a follow up on

doing just this. It is just a semi-complex DIY procedure. Basically

taking your 1" bulkhead and using plastic epoxy to attach

1.25" PVC fittings to it.

Gets you another 100 GPH or so.>

I thought of venting the over flow return to the sump.

<Any overflow should be.>

I know in a house if your vent is plugged the flow is cut in half. Also

would increasing the over flow return hose have any effect on the

amount of water going through the bulk head e.g. 1 inch bulk head tied

to 1-1/2 inch pvc pipe. Any experience or suggestions.

<If you have access to it I would drill the back of the tank inside

the box for larger bulkheads. See:

http://glass-holes.com/>

I have 150 gallon tank with a 60 gallon sup.2 1inch overflows and a Mag

18.

Thanks I wish I found this out 8 years ago, Would have used bigger over

flow bulk heads.

<Well, we have all been there! I am sorry to tell you the flow rates

listed in the article you are referring to were vented! People hate to

hear it, but it is what it is! Scott V.>

1 inch over flow bulk heads. 2/14/11... double

posted... idiot

Hello

I have a question for you. I am one of the lucky ones that have 1 inch

bulk heads the found you site and discovered there actual flow rates.

Is there any way to increase there flow rate?

<Not really; no>

I thought of venting the over flow return to the sump. I know in a

house if your vent is plugged the flow is cut in half. Also would

increasing the over flow return hose have any effect on the amount of

water going through the bulk head e.g. 1 inch bulk head tied to 1-1/2

inch pvc pipe. Any experience or suggestions.

<Folks have been writing re these trials the last few months, but

they're not realistic modifications, nor safe>

I have 150 gallon tank with a 60 gallon sup.2 1inch overflows and a Mag

18. Thanks I wish I found this out 8 years ago, Would have used bigger

over flow bulk heads.

<Do read here:

http://www.wetwebmedia.com/thrhullsiz5f.htm

and the linked files above, till you're satisfied that you're

aware of your choices here. I'd bite the proverbial bullet and

get/use internal water movement mechanism/s, and the existing two one

inch through puts for the sump/refugium, run it on low enough that one

line can/will suffice, and rig a return over the top of the tank. Bob

Fenner>

Number and size of holes it is safe to

drill on an acrylic tank `12/27/10

Hello and thanks for providing me with many hours of informative

reading.

My tank is a 40g SeaClear (36"h x 15"w x 16"h) with

1/4" thick acrylic.

Before setting up the tank I drilled a single 1.5" hole for a

drain to the sump. Obviously I should have drilled a few more. I'm

considering drilling additional holes now and am wondering how many

1.5" holes it is safe to drill in the back of the tank at the top

without weakening the tank to a point that would cause concern.

<Quite a few.>

I'm thinking that I would like to have 5 total (1 sump return, 2

sump drains, and 2 in/out for a canister filter).

<This will be fine, though I would opt for 1.5" lines (actually

require 2.5" hole) for the drains.>

Also, I'll probably empty about half of the water from the tank to

do this.

Am I courting disaster by doing the drilling with water still in the

tank?

<Well, I will advise you to empty the tank. But I personally do not

always practice what I preach.>

I have an unused tank that I could have on stand-by, but if a big crack

formed it would still be a big mess.

<Yep, for the time it takes to tear down a 40 I would do it

empty.>

Thanks for any advice you can provide.

-Brett

<Welcome, Scott V.>

>

Drilling Acrylic/Plumbing

12/10/10

<Hello Sanford>

I've reviewed what I can on the site. Can't find anything

regarding my specific question. I want to drill a drain hole in the

bottom of an acrylic tank (60 gallons, 1/4", bows a lot when

full). I plan to build an overflow and have a standpipe inside. How

close to the edge can I drill. I saw you tell another enthusiast

1" from the edge. That would work for me and my particular plans,

but it would be a better solution if I could get a little closer. It

seems to me that drilling through the bottom would give me some leeway.

The stand top is a 3/4" sold piece of particle board.

<I would put a couple of coats of polyurethane on this

board.>

Granted, I will need to cut through that to allow the drain pipe access

to below. But it seems to me that there will still be a substantial

amount of support to the bottom of the tank since it lays flat against

the top of the stand. Any input would be great.

<First, I'd like to recommend you install a 1-1/2"

standpipe. A one inch standpipe will only allow about a 350gph flow

rate. See here. http://www.wetwebmedia.com/BulkheadFloRateArt.htm

With a 1-1/2" bulkhead fitting, I doubt you could get any closer

than one inch from the edge. You have to allow room for the bulkhead

fitting nut with molded flange

Thanks

<You're welcome. James (Salty Dog)>

Sanford

Mag 12 / 100G / 1.5 stand pipe (Durso)

12/6/10

Hello Crew,

<Hello.>

Just one quick question, Is Mag 12 too much for a single overflow with

1.5" (Durso) stand pipe on a 100 G reef tank?

<Once all the plumbing is accounted for a 1.5" will technically

handle the flow of a Mag 12, but you will be right on the edge of the

overflow's capacity, with no redundancy. The slightest little

occlusion will lead to your tank overflowing!>

Thanks/ Jun

<Welcome, Scott V. Do take a look here:

http://www.wetwebmedia.com/SystemPIX/PlumbingPix/Oneinchart.htm>

Overflow flow rate

11/08/10

Evening crew

<Good evening.>

I have a plumbing question for you.

<Okay.>

I have a 155 tank with dual overflows on the sides. When I purchased

the tank, the overflows came predrilled with 1" slip bulkheads so

would assume that the hole is drilled at 1 3/4" to accommodate a 1

1/2 inch thread. I'm trying to figure out a way to increase the

inside diameter of the pipe. In a perfect world I would have a 1 1/2

threaded pipe on either side. which would probably make my id 1

1/4". Are you aware of any such bulkhead or idea that could allow

me to do this?

<Yes, a few DIY options.>

An option that I have been considering is to get a threaded plastic

nut/washer and use PVC glue to seal it about halfway down on a standard

11/2 threaded PVC. Have you heard of anyone doing this in the past?

<I have done basically the same thing a few times over the

years.>

I've tried all my local plumbing guys and Google searches trying to

find such a product with no avail. Might be a good new product for a

PVC company to offer to the trade (wish I knew one so I could get a

kickback).

<Haha, I thought so too a while back. After writing a how to for a

certain forum and promptly being kicked off that forum for saying a

1" bulkhead will not flow a zillion gallons an hour I realized

such a product may not be well perceived in the market (and now that I

look it appears the post was removed for my witchcraft). After years of

selling overflows that do indeed flow I now know that most either

believe a 1" bulkhead does flow an infinite amount of water or

they think that the pump is flowing way more than it actually does.

This does not even take into account the many times I have beat my head

into the wall trying to get people to consider the value of overflow

redundancy! All that being said, PVC cement can work. Do realize that

many of the bulkheads sold in the trade are actually ABS (yeah, I know,

everybody uses PVC cement, but for a butt joint I would not at all!). I

ended up using the two part plastic epoxies available from hardware

stores to bond an 1.25" slip fitting to the 1" bulkhead on

the end inside the overflow. The outside is a bit trickier to do

reliably. Some of the 1" bulkheads out there will actually allow

you to screw on a 1.25" threaded fitting to the outside of the

bulkhead. None fully, they are not pipe thread (on which they taper to

a thicker thread the farther you screw onto). The HydroAir brand works

well, you can get 4-5 turns onto one of these. Typically you can find

these at spa supply companies, Custom Aquatic used to and may well

still carry these. If you can find a 1.25" female pipe fitting in

steel (not so common around here), you can use this to "clean

up" the threads on the bulkhead, allowing you to screw the PVC

fitting on even further.>

Anyway, let me know your thoughts Chris

<Scott V.>

Overflow meas. requested

9/21/10

Salutations once again,

<Hello Richard.>

As always, the research in the marine world includes/comes back to The

Crew. I am attempting to locate info regarding the overflow

surface-skimming portion of the design, and have hit a wall.

<Okay, I will either help you in a great way or confuse you into

oblivion.>

The calculators/explanations for measurements regarding the

placement-distance and depth vs. actual size of the teeth at the

surface of the water, along with number of teeth per surface area of

tank appears to be sadly missing.

<This is because calculations do not work here. The calculations out

there (they are) are for large scale weirs, such as those crossing

large rivers.

When applied to even the largest of aquariums there is really zero

relevance due to the surface tension, the cohesion of water. If it were

not for this property water would not form a drop on the kitchen

counter.

But it does, while at the same time it will not take such a form as a

puddle. Volume does count in these calculations, something lost on many

that advocate for "surface skimming".>

I have read in the site's FAQ sections a reference to

ozreef.org

<<RMF just checked... it IS gone. A shame. A collection of very

useful and inspirational DIY info.>>

but the site appears to be gone.

<The reference I believe you refer to is indeed still there, though

vague.>

Is there a calculator/explanation showing "flow through

teeth" vs. "number of teeth and size per foot" that

could be passed on please?

<Not really. At the scale we deal with in aquariums a 1/16" of

in inch can be a mile. Any calculation here is a blanket, not based in

what will really happen. The reality is every single overflow

throughput calculator

on the internet falls to the same downfalls.>

Although you are probably tired of hearing it - your patience and

assistance is greatly appreciated.

<Totally ignore "surface skimming". I do realize there are

certain authors (one in particular) out there in the forums that has

made a name for themselves by advocating surface skimming. Reality? Two

examples. Think about the 20000 gallon pool, not all that large for

your typical built in pool. Skim that surface for an hour or two per

day with the typical built in weir. Nothing on top after. All that

sinks lower happens when the surface skimming is not happening. These

are not hydrophobic, merely floating of the surface due to cohesion.

Once the cohesion is broken they sink. If leaves in a pool were truly

hydrophobic they would easily be skimmed in that time frame. The other

example is that of a 1000 gallon tank running 100 gph through the sump.

Nobody would do this! But think about it. At that rate you would be

running 2400 gallons per day through the sump, plenty of surface

skimming in 24 hours! Many relate surface skimming to dwell time in a

skimmer, these are completely separate issues.

Do also consider the increased flow we do (for good reason) run in our

marine tanks today. The surface is not stagnant! Although the compounds

we seek to take out are hydrophobic, it does not mean they just sit on

the surface no matter what. By agitating the surface we do mix them

back in.

The compounds will eventually end up back on top, assuming the surface

is smooth and dead! Forget surface skimming, if it were to work like

those have proposed in the forums a tank would be way too sterile

anyhow!>

Thank You.

Richard J.C.

<Welcome, sorry for the lengthy reply. I just feel a need to set

this subject straight! Rather than just making claims, I have the

numbers to back this one up! Scott V.>

Re: Overflow meas. requested 9/21/10

Hiya Scott,

<Hi Richard!>

Thank you for the prompt and informative reply (big grin here). Lengthy

in this instance is good... as with skimming, more is good. And please

pardon my comments as an attempt at clarification for my (and

hopefully, other's) benefit.

<Okay!>

My take on the supplied (and appreciated) information, is that the

"teeth" relevance are subject to the effects of pressure and

gravity more so then actual mass transported at one time?

<Actually, yes!>

By this, it could be assumed that a larger pass-through area (the

teeth), either by size of opening - or quantity, would only supply an

advantage of a smoother flow and/or quieter operation... but would not

effect actual volume?

<Well more/larger/longer teeth will flow more if more is suppled.

But at a given volume more teeth will result to the water running

lower, smoother, quieter within, yes.>

Is this why some in the hobby suggest a trough-style overflow

(especially for external overflows) as opposed to a single standpipe

style?

<Haha, I guess. I have yet to figure out that one, some don't

even want an overflow inside the tank!>

If my take on this is accurate (insert judgment here :)

A 65gal tank with a surface skim overflow of 4in x 4in with a method of

breaking the surface tension (say, a rotating powerhead) would have a

greater effectiveness then a larger overflow with no surface tension

being broken?

<Not really, but in reality they will function the same in this

application.>

If this is accurate, the "teeth" could then be the mentioned

1/16in (an example, I realize) but a greater benefit would be to extend

them to - say - 1/2in deep instead of say 1/4in to allow for more draw

from 'deeper' in the tank. But the overall length of the

'teeth' (linear total) is actually not relevant.

<Well here is where that cohesion property of water makes linear

calculators almost useless in these applications. The water will flow

3/8-1/2" up into the teeth even at the slowest of flows. I really

can't quantify to you if it is taking the top 1/16" or the top

1/4", what I can say is the very surface itself is effectively

skimmed.>

You mention dwell time. From what I have read (and yes, the sources are

in suspect pending confirmation), that refers to the relative amount of

time the particulate remains in contact with the bubbles within the

skimmer (not the overflow) to bond and be transported to the

ever-fragrant skimmate (sp.?) cup. I believe I now understand that

surface skimming refers to the amount of particulate removed at surface

level, with regard to volume of water passing over the overflow. Am I

correct in assuming that the amount of 'scum' would only

increase marginally if the surface tension was not broken?

<Yes, the increase would be very marginal in my opinion. Most

advocates for surface skimming with long weirs do it in hope to get a

more concentrated surface water to the skimmer. With the washing

machine type flow most use today this is all a nice thought, but not

the make or break of a system.>

The long and short of this is: I plan a 48x30x20h sys - full reef,

peninsula style. My overflow could then have the teeth measuring at

1/2in deep and 1/4in wide (the gaps)... and to reduce flow

pressure/noise, I could do say 20-22 linear inches with the surface

tension being broken in the main body of the tank, and there would be

little or no measurable difference reversing these teeth dimensions in

a system of this size? As long as the volume of water passing over is

consistent with a system <1/4" is a good size for tooth gap. It

allows flow and keep out critters without being too loud.>

this size - I believe 600gph is sufficient?

<600 gph is fine for this system through the sump. I would

personally set you tooth height a bit taller. You will find at around

20 inches of 1/4 teeth and this flow your water level will be about

1/2" up from the bottom of the teeth.>

I'm certain at this point, your comments are going to be needed to

clear this jumble up - not just for me - but for those poor souls who

will have read this in the future.

<Haha, you stepped into a subject that is a passion of mine for some

strange reason!>

As for your comment regarding 'setting this subject

straight'... I couldn't agree more. Thank you for your patience

and concern towards this issue.

If the above is not even close... just roll up the newspaper and

swing!

Richard J.C.

<Welcome and thank you. It sounds like you got it, build that

overflow!

Scott V.>

Drilling/Plumbing an Oceanic

120'¦and a WWM Book on Such? -- 08/28/10 <oh

yeah!>

Hey Guys your site is awesome.

<<We (guys and gals) are happy you think so>>

I have read many emails and answers on this subject but still need some

specifics.

<<Okay>>

I am attempting to assemble a fairly high end 120 Gal after the

installer at the LFS quit right after most of my equipment was

delivered.

<<Mmm, bummer'¦ But if you are a little bit

'handy' and willing to do your research, this can be quite

rewarding for you>>

This will ultimately be a high end SPS tank and while money is always a

consideration I have already spent around 6K on this project so I want

to do it right the first time.

<<Indeed>>

I have a brand new Oceanic 120 (reef ready)

<<So 'they' say'¦ The 1' through puts are

lacking re their size--but you can make do>>

and large high flow sump 41"L x 24"W x 30"H. The return

pump is a Dart Gold.

<<This is way 'too much' pump (3800gph) for the existing

1' stock gravity drains (600gph-700gph--combined!)>>

After reading on your site about the dangers in undersized drain

bulkheads it sounds like I need to drill the drain holes from the

existing 1" to 2".

<<Yes'¦ And install a gate-valve on the output side of

the pump to temper flow even further as necessary. But, have you even

considered the 'noise' that flushing this much water through

your system/sump will make? '¦not to mention the

plumbing/bubble hassles? It's your system and certainly your

call--but I always recommend folks limit flow through their sump to

only a few hundred gallons, and utilize the many makes/models of

'prop-pumps' available today for generating water flow within

the system. You won't realize much if any initial money savings

versus purchasing one over the other (in fact, the prop-pumps will

likely cost more to start with), but the savings re reduced plumbing

hassles, reduced operating costs, much better water movement, and lower

'piecemeal' replacement costs more than make up the difference,

in my opinion>>

Of course this is a very heavy tank and I would prefer not taking it to

a glass guy to have it drilled if that can be avoided.

<<You can avoid drilling it altogether, re my previous

argument>>

Can I drill this myself?

<<I do think the Oceanic aquariums are 'non-tempered'

glass so yes, you can drill it yourself (do check with the manufacturer

to be sure before you begin)>>

I have a full shop

<<Hey! Me too!>>

and have been doing DIY stuff for years and am fairly competent.

<<Ah, okay--I feel better about this then. You should need little

more than to look up/review the process/steps involved>>

Can you suggest a source for the proper bit?

<<Well my friend, you can spend a whole lot or a whole little

here. If you are only going to drill a few holes then the cheap bits

suffice quite well in my experience. I find I can get 8-10 holes out of

one before it needs to be replaced. Simply do a search on the Net for

'diamond core drill bits,' and let your pocketbook be your

guide>>

Assuming I go to a 2 1/4" hole what do I replace the existing

plumbing pieces in the overflow with?

<<Not sure I am following you here'¦ If you mean you are

drilling the larger holes in 'new ' locations and need to plug

the existing drains, then I would silicone a glass 'patch' over

the existing drain holes (be sure to use glass of the same thickness as

the panel/bottom, and overlap all edges by 1-inch'¦2-inches if

there is room>>

Is there room for to enlarge the 1" hole to 2 1/4"?

<<You will have to determine whether the existing overflow boxes

are large enough for this (you may bell have to remove and enlarge

these), but be sure to keep the edges of any new holes at least

1.5' from the edge of any panel you drill through to reduce the

chances of 'cracking to the edge'>>

Should the 3/4 bulkhead return holes be left the same size?

<1' would be better if you stick with the pump you describe and

wish to maximize flow'¦but the ¾' returns can

'work'>>

Second question. This tank will eventually be installed in a different

location with a basement fish room containing the sump.

<<Ah--I see>>

For now (about a year) they will be installed side by side in the

basement.

<<Okay>>

The top of the sump is above the level of the bottom of the tank. As a

result, the drain lines will have to come out of the bottom and then

rise up over the sump top before going into the bottom of the sump

which is about 18" below the bottom of the tank. Would it be

better to drill the side of the sump and install (2) 2" bulkheads

to allow the drain lines to feed directly into the sump instead of up

and over utilizing the two existing bulkhead holes in the sump top?

<<That depends on your desired flow rate through the sump. The

first configuration will limit the flow from the gravity drains--if you

wish to 'maximize' capacity then yes, you will need to

configure the drain lines so the water will 'fall' the entire

route to the sump>>

What is the title and topic(s) of the book that one of you has written

on this and related subjects?

<<Uh-oh!--did Bob put you up to this? [grin] He has been after a

couple of us to do just that for several years

now'¦<<I'll say!>> which of

course, we haven't. Your best bet is likely to do Net

searches/search the aquarium DIY sites as I don't rightly recall a

good 'book' for what you wish, at the moment>>

Thanks in advance!

John C

<<Happy to share, mate--and do let me know if you wish to discuss

any of this further'¦ Eric Russell>>

Gyres, Bulkheads and Flow Rates/Marine

Set-Up/Marine Plumbing 8/28/10

Hi Guys,

<Hello David>

It is some time since I have been here having set up a 50g five years

ago.

We are now in the process of building a new house and I have the

opportunity to build a 5ft x 2ft x 2ft in wall tank. Ideally I would

like to design a tank that did not require any internal powerheads or

pipework.

<Sounds nice.>

I have been researching the build on WWM and elsewhere and have come

upon the idea of gyre flow. However there is a limited amount of

information out there and wonder what your feelings are on this?

I am considering using a vertical gyre with a "spine"

arrangement of live rock down the midline of the tank. An inlet would

be positioned around 12" high and 4" in from the front and

back on each end corner of the tank allowing alternation of the gyre

direction. Is one inlet per "corner" sufficient?

<Yes, more to follow below.>

My specific questions relate to flow rate, overflow design and outlet

bulkhead sizing. Various calculators and sites provide different

estimates and figures, theoretical or practical, I don't know.

While the viewable tank length will be 5 ft I can extend it by up to

6" at one end and use the entire width of the tank, 24", as

the weir, or up to 4" at both ends and have two 24" weirs and

overflow boxes.

The volume of the tank is nominally 150 US gallons.

For my sump, to achieve a turnover of 3x-5x,or 450-750gph what size and

how many bulkheads should I use?

<For reef systems, the recommended flow rate should be at least 10X

the tank volume and I would size the pump for at least 20-30% more than

anticipated to allow for any head loss. If the sump and pump are to be

located in the basement, I'd size even higher and use a pressure

type pump rather than a circulation type pump. Ball/gate valves can be

used to

control the flow rate on each return. I would have the tank constructed

with built-in overflows at each rear corner of the tank using 1

1/2" drains, one per overflow box. A 3/4" return line in each

corner will provide the necessary flow rate and most tank manufacturers

will incorporate the return line inside the overflow box. Seeing as how

you want no internal plumbing, I would suggest the use of a rotating

return device such as Sea Swirls. Take a look here.

http://premiumaquatics.com/store/merchant.mvc?Screen=PROD&Store_Code=PA&Category_Code=&Product_Code=SEASWIRL

The use of a device like this will

provide flow to all areas of the tank.>

I have been looking at the Calfo overflow setup, any thoughts?

<If it were mine, I'd go with the corner overflows.>

Does the use of a comb significantly reduce the flow rate over the

weir?

<No, as long as the total square inch area of the gates in the weir

are greater than the inside area of a 1 1/2" PVC pipe.>

I know I should have a turnover rate of 10x+ through each pair of

inlets on the closed loop but what flow rate should I aim for at each

inlet? i.e. should I balance the flow between them or set one high and

the other as a booster to maintain the gyre?